Biomass boilers are a renewable energy technology. They are increasingly favored and popular for energy-saving heating. Mainly due to its significant operating cost reduction compared to traditional heating methods. Traditional heating systems use coal or gas. They have the problem of high fuel costs. But, biomass boilers use cheap biomass fuels, like wood chips and straw, to greatly cut operating costs. This cost advantage makes EPCB Boilers' biomass boilers a top choice for companies and individuals.

At the same time, biomass boilers have low operation and maintenance costs. This is because they have abundant fuel sources and stable prices. These reduce the long-term energy cost pressure of enterprises. In addition, EPCB Boilers' biomass boilers have kept innovating. They improve the efficiency and stability of the equipment. This further cuts operating costs. Biomass boilers can cut operating costs. They cost less than traditional heating methods. This is a key reason for their popularity in energy-saving heating.

What is A Biomass Boiler?

EPCB Boiler makes the biomass boiler. It uses biomass as fuel. It makes steam or hot water to supply heat for industry, commerce, or homes.

Biomass boilers can typically use several types of biomass fuel, including but not limited to:

·Wood biomass: such as wood chips, cassava, sawdust, and other wood processing by-products.

·Crop straw: such as corn straw, wheat straw, and other crop waste.

·Energy crops: Such as energy plants, reeds, sugarcane bagasse, and other specially grown energy plants.

·Industrial waste: waste generated during industrial production such as waste paper, waste fiber, and waste wood.

Biomass boilers made by EPCB Boiler Manufacturing use a principle like traditional boilers. However, the fuel and combustion processes are a bit different. Generally speaking, its working principle includes the following steps:

·Feeding system: Biomass fuel is transported to the boiler combustion chamber through the feeding system.

·Combustion process: In the combustion chamber, biomass fuel is mixed with air or other oxidants, and heat energy is released through ignition and control of the combustion process.

·Thermal energy transfer: The released thermal energy is transferred to the water in the boiler, heating the water and converting it into steam or hot water.

·Thermal energy utilization: Steam or hot water is transported to equipment or systems that require heating for heating buildings, processing, or other purposes.

·Exhaust gas treatment: The exhaust gas generated during the combustion process is purified through the treatment system to reduce the impact on the environment.

EPCB manufactures biomass boilers. They use biomass as a renewable fuel. They meet the need for heating and hot water by burning the biomass to make heat. They have the advantages of environmental protection, economy, and sustainability.

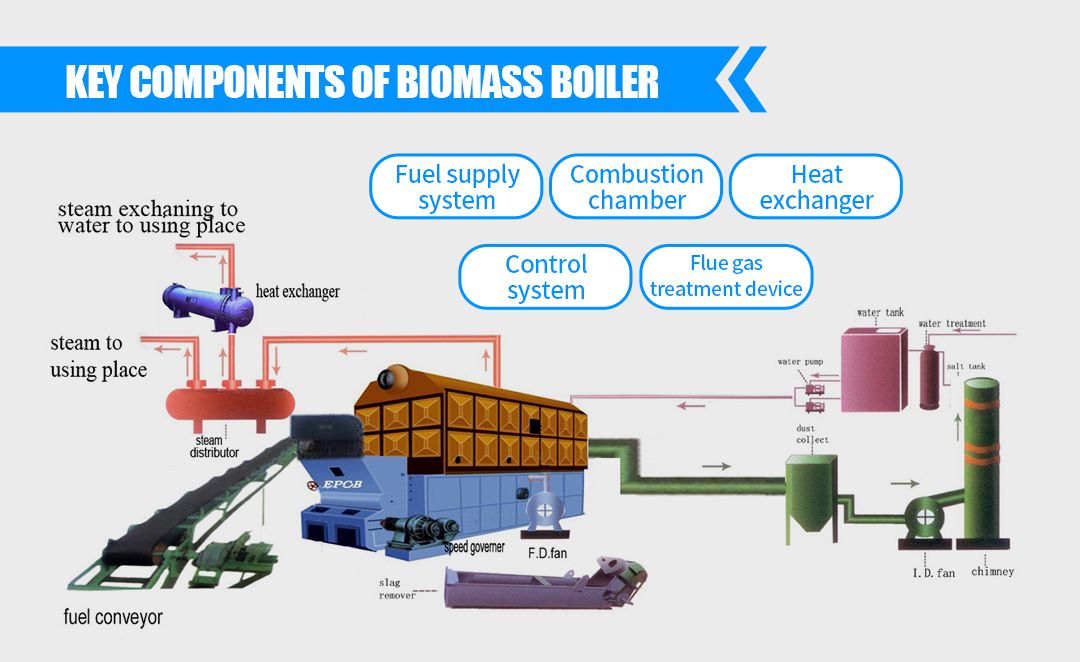

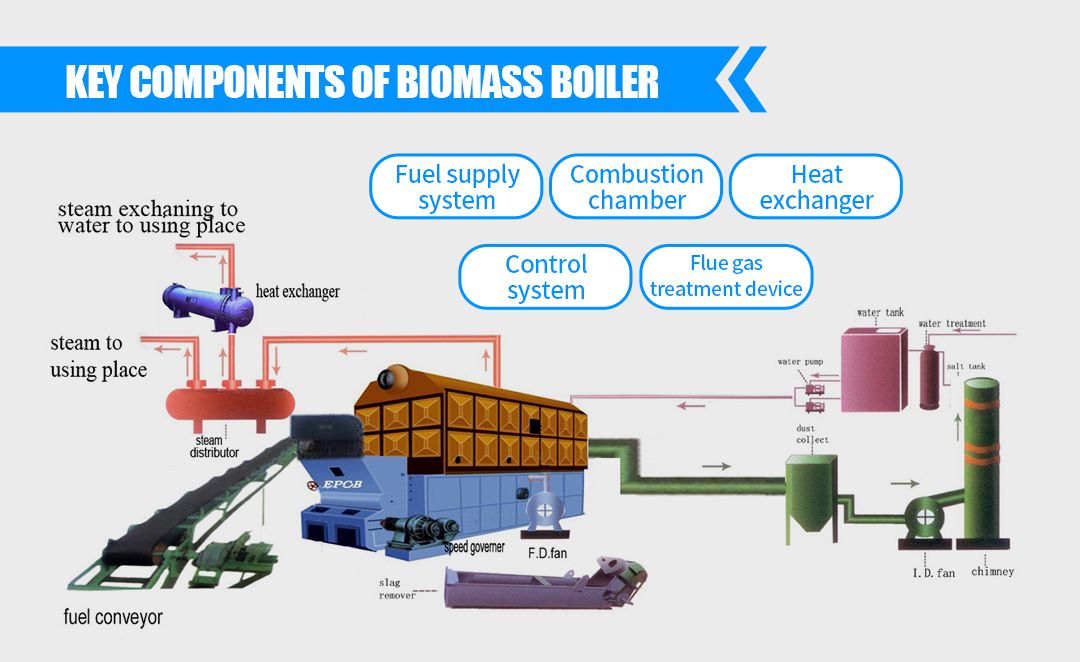

Key Components of Biomass Boiler

The key parts of the biomass boiler produced by EPCB boiler include the following:

Fuel supply system: EPCB's biomass boilers have an efficient fuel supply. It ensures stable delivery of fuel to the combustion chamber and improves fuel use.

Combustion chamber: EPCB's biomass boilers have an advanced combustion chamber design. It ensures full burning of biomass fuel. This design maximizes the release of heat energy and boosts energy efficiency.

Heat exchanger: EPCB's biomass boiler has a good heat exchanger. It transfers the heat released by combustion to water well. This achieves efficient energy conversion and improves energy use.

Control system: EPCB's biomass boilers have advanced control systems. The systems can monitor and adjust the boiler's operation. They ensure that the boiler works well and cuts energy waste.

Exhaust gas treatment facilities: EPCB's biomass boilers have exhaust gas treatment facilities. They can cut the impact of the gas from combustion on the environment. At the same time, it helps to recover the energy in the exhaust gas and improves the overall efficiency of energy conversion.

These parts work together. They ensure that EPCB's biomass boilers achieve high efficiency, energy conservation, and environmental protection during energy conversion.

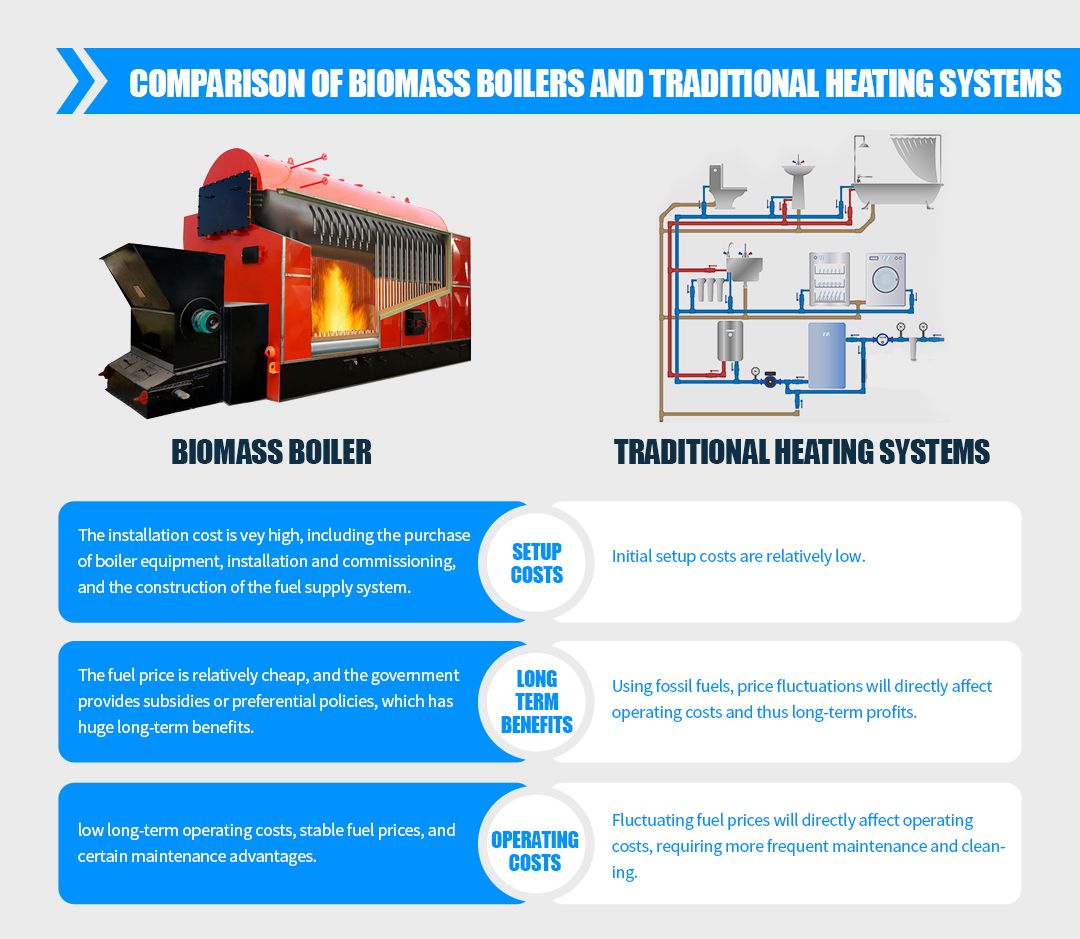

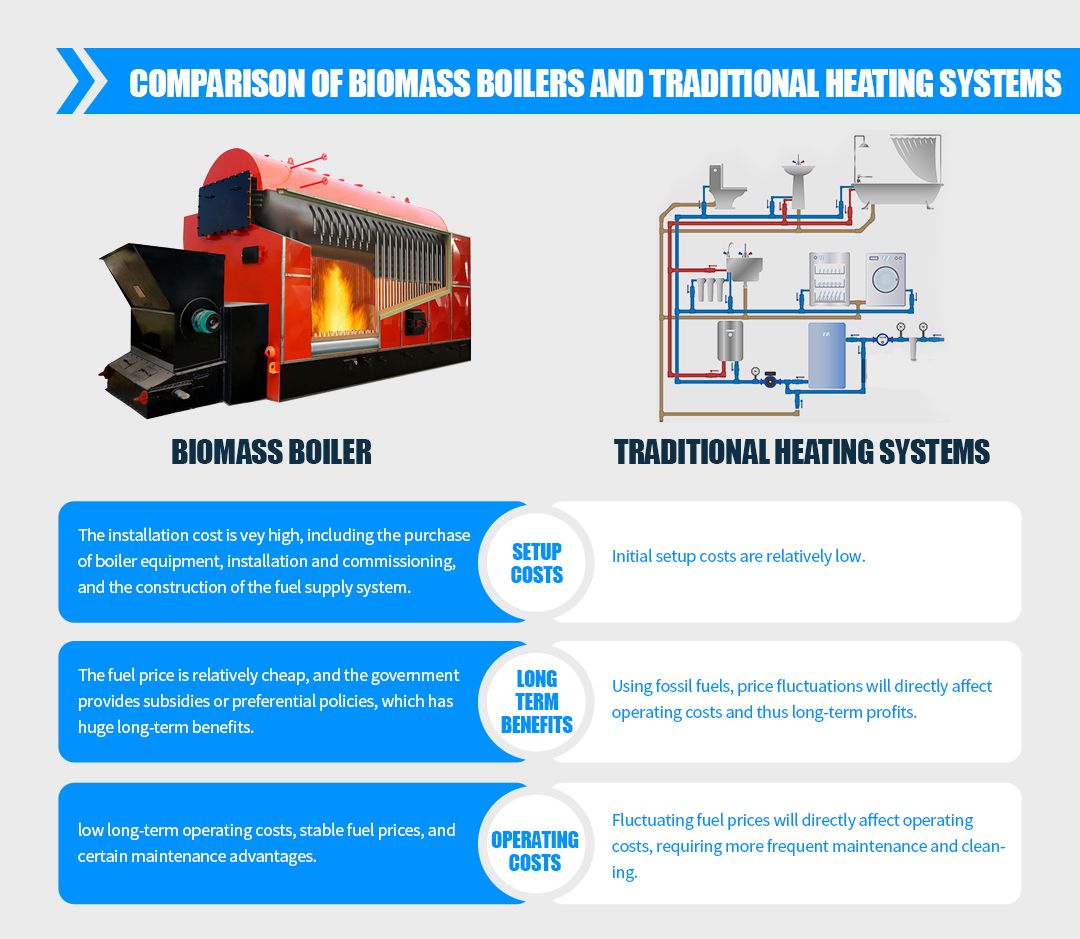

Comparison With Traditional Heating Systems

Comparing a biomass boiler to a traditional heating system has many aspects. These include setup costs, long-term benefits, and operating costs. Here's how they compare:

Initial Setup Costs Versus Long-Term Benefits

Biomass Boiler: The setup cost of a biomass boiler is high at first. It mainly involves buying the boiler equipment, installing and commissioning it, and setting up fuel supply systems. However, biomass fuel is relatively cheap. Also, the government often offers subsidies or preferential policies. So, biomass boilers can usually bring big long-term benefits.

Traditional Heating Systems: The initial setup costs of traditional heating systems are relatively low, but in the long run, they use fossil fuels such as oil or natural gas. Fluctuations in fuel prices will directly affect operating costs and thus long-term profits.

Operating Cost Comparison

Fuel Price: Traditional heating systems use oil as fuel. Fluctuations in fuel prices directly affect their operating costs. Fuel prices are rising. They will increase heating costs. But, the price of biomass fuel used in biomass boilers is stable. It is less affected by market fluctuations.

Maintenance: Maintaining biomass boilers is easier and cheaper than traditional heating systems. Biomass boilers burn cleanly. The residue after burning is small. This reduces boiler cleaning and maintenance costs. An oil or gas boiler is in a traditional heating system. It may need more frequent maintenance and cleaning to work well.

Biomass boilers have lower long-term operating costs and stable fuel prices. But, their setup costs are high. At the same time, biomass boilers also have some maintenance advantages. These advantages further lower long-term operating costs.

Government Incentives and Subsidies

The installation of biomass boilers is eligible for many financial incentives. These incentives promote the use of renewable energy and energy conservation. They also promote emission reduction. They do this by cutting the upfront cost of biomass boilers. Here are some common financial incentives:

Subsidy and incentive programs: Many governments and local governments offer subsidy and incentive programs. They aim to encourage businesses and individuals to install biomass boilers. Governments often base these subsidies and incentives on: the power of installed biomass boilers, energy efficiency ratings, or the number of replaced fuel boilers.

Tax incentives: Some countries offer tax relief for biomass boilers. They provide reductions in value-added tax, corporate income tax, or personal income tax. These tax incentives can reduce the initial investment costs of biomass boilers and make installation more attractive.

Loans and financing support: Governments and banks may offer loans and financing for biomass boilers. They are specifically for biomass boiler installations. The loans often have lower interest rates. They also have flexible repayment options. These features help businesses and people more easily finance biomass installations. boiler.

Carbon emission quota trading: In some countries or regions, companies that install biomass boilers can get carbon emission quotas. They can also get carbon credits. These credits can be traded on the carbon emissions trading market, bringing additional revenue to the company.

These incentives can greatly cut the upfront costs of installing a biomass boiler. This will increase the overall cost-effectiveness of a biomass boiler. For example, subsidies and incentives cut the capital needs for installing biomass boilers. Tax incentives cut the tax burden of enterprises or individuals. Loans and financing support cut financing costs and burdens. Carbon emission trading benefits enterprises. Comes an additional source of income. These measures shorten the payback period for installing a biomass boiler. They make the return on investment bigger. This improves the overall cost-effectiveness.

Environmental Impact and Sustainability

Using renewable resources such as biomass boilers can bring many environmental benefits, including a contribution to a reduced carbon footprint:

Reduce greenhouse gas emissions: The amount of carbon dioxide released when biomass boilers burn biomass fuel offsets the amount of carbon dioxide absorbed during the growth of biomass, forming a closed cycle. Therefore, the use of biomass boilers can greatly reduce greenhouse gases such as carbon dioxide. emissions, helping to slow down the rate of global climate change.

Reduce the use of fossil fuels: Biomass boilers use biomass as renewable energy, which not only reduces the demand for limited fossil fuels but also reduces environmental pollution and ecological damage caused by the mining, processing, and transportation of fossil fuels.

Promote forest management and protection: Biomass fuels usually come from renewable resources such as waste wood and crop straws. By effectively utilizing these resources, they promote forest management and sustainable use of farmland resources and help maintain and protect forest ecosystems. healthy.

Improve air quality: The combustion process of biomass boilers is relatively clean and emits fewer pollutants, such as nitrogen oxides and sulfur oxides. Therefore, the use of biomass boilers can reduce the emission of air pollutants and improve the air quality of the surrounding environment.

Reduce energy dependence: Using biomass boilers for heating or hot water production can reduce dependence on traditional energy sources such as coal and natural gas, increase the diversity of energy supply, and improve energy security.

To sum up, biomass boilers, as a heating method that utilizes renewable resources, have a very significant positive impact on the environment. In particular, they play an important role in reducing carbon emissions and helping build a low-carbon and environmentally friendly society. A sustainable future.

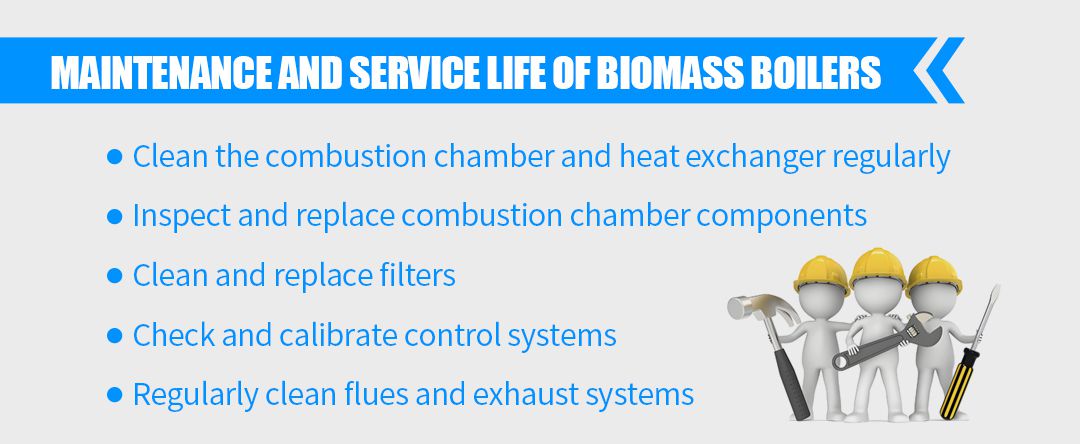

Biomass Boiler Maintenance and Lifespan

EPCB Boilers Maintenance requirements and schedules for biomass boilers may vary depending on the model, specification, and specific usage, but in general, here are some common maintenance requirements and schedules:

Clean the combustion chamber and heat exchanger regularly: Regular cleaning of the combustion chamber and heat exchanger is key to keeping your boiler running efficiently. Carbon deposits or residues in the combustion chamber will affect combustion efficiency, and dirt on the surface of the heat exchanger will reduce heat energy transfer efficiency. A thorough cleaning is usually recommended quarterly or semi-annually.

Check and replace combustion chamber parts: Regularly check and replace key parts in the combustion chamber, such as nozzles, igniters, burners, etc., to ensure their normal operation. This can usually be done on an annual or biennial basis.

Clean and replace filters: Clean and replace air and water filters regularly to keep your boiler system functioning properly. The air filter is generally cleaned every quarter or half a year, and the water filter is replaced every year or two years.

Check and calibrate the control system: Regularly check and calibrate the boiler's control system, including temperature, pressure, and flow controllers, to ensure it is accurate and reliable. It is usually recommended to have an inspection every six months or one year.

Regularly clean the flue and exhaust system: Regularly clean the dust and dirt in the flue and exhaust system to ensure normal exhaust flow and reduce fire and safety risks. It is generally recommended to clean up every quarter or half a year.

The specific arrangement of the maintenance schedule should be adjusted based on the actual use of the boiler and the manufacturer's recommendations. Regular maintenance and upkeep can extend the service life of biomass boilers, improve operating efficiency, and reduce failure and safety risks. Therefore, regular maintenance is key to ensuring the safe and reliable operation of biomass boilers.

Conclusion

Biomass boilers offer significant advantages as a heating solution in terms of sustainability and cost-effectiveness. First, it uses renewable resources as fuel, such as woody biomass, crop straws, etc., which will not be exhausted and will not cause permanent damage to the environment.

Compared with traditional fuels, the use of biomass fuels can significantly reduce greenhouse gas emissions, help reduce carbon footprints, and mitigate the impact of climate change. In addition, the government usually provides various financial incentives, such as subsidies, tax incentives, etc., to support the installation and use of biomass boilers, thus reducing the initial investment cost.

Biomass fuel prices are relatively stable and low, making biomass boilers less expensive to operate, helping to reduce overall energy bills. In addition, the use of biomass boilers promotes sustainable development, reduces dependence on limited resources, reduces environmental pollution, and helps protect the natural environment and ecosystems.

Therefore, it is a reasonable choice to consider biomass boilers produced by EPCB Boilers as a sustainable and cost-effective heating solution that can not only meet the needs of home heating but also contribute to environmental protection and economic savings. If you have any questions when choosing a biomass boiler, please contact EPCB boiler engineers and we will serve you wholeheartedly.

FAQ

What are the most common types of biomass fuel?

The most common types of biomass fuel include:

Woody biomass: includes wood processing by-products such as wood chips, cassava, sawdust, and bark.

Crop straw: such as corn straw, wheat straw, rice straw, and other crop waste.

Energy crops: specially grown energy plants, such as sugarcane bagasse, corn stalks, energy forests, etc.

Industrial waste: including waste paper, waste fiber, waste wood, and other waste generated during industrial production.

Municipal solid waste: can be processed through biomass waste treatment facilities, such as kitchen waste, waste paper, etc.

Bioenergy waste: such as by-products generated during biomass energy processing, including biomass charcoal, biomass oil, etc.

These biomass fuel types play an important role in the utilization of biomass energy. They are renewable, clean, and environmentally friendly, and are widely used in biomass boilers, biomass power generation, biomass fuel, and other fields.

How often does a biomass boiler need maintenance?

Biomass boilers require regular maintenance to ensure they operate safely and efficiently. Maintenance frequency usually depends on several factors:

Frequency of use: The frequency of use of the biomass boiler will affect its maintenance cycle. If a biomass boiler is run for long periods each day, then more frequent maintenance may be required, whereas a boiler that is used less frequently may be able to benefit from extended maintenance intervals.

Boiler models and specifications: Biomass boilers of different models and specifications have different maintenance requirements. Some larger boilers may require more frequent maintenance, while smaller boilers may require less maintenance.

Operating environment: The environmental conditions in which the boiler operates will also affect the maintenance cycle. If the boiler operates in an environment with a lot of dust, high humidity, or large temperature changes, more frequent maintenance may be required.

Generally speaking, the maintenance cycle of a biomass boiler is usually between a few months and a year. Specifically, it can be carried out according to the following suggestions:

Regular cleaning: Conduct a thorough cleaning every quarter or half a year, including cleaning components such as the combustion chamber, flue, and heat exchanger, to maintain the efficient operation of the boiler.

Inspect and replace key components: Conduct inspections every year or two years to check key components such as nozzles, igniters, burners, etc., and replace damaged or worn components promptly to ensure the safe operation of the boiler.

Maintain the control system: Check and calibrate the control system every six months or one year to ensure the normal operation of equipment such as temperature, pressure, and flow controllers.

The specific schedule of maintenance intervals should be adjusted based on the actual use of the boiler, the manufacturer's recommendations, and local environmental conditions. Timely maintenance can extend the service life of biomass boilers, improve operating efficiency, and reduce failures and safety risks.

Can a biomass boiler heat my entire home?

A biomass boiler can provide heating for an entire home, but suitability depends on several factors:

House size: The size of the house that a biomass boiler can heat depends on its power size and design features. Generally speaking, biomass boilers suitable for home heating have a wide power range and can cover a variety of house types, from small apartments to detached houses.

Thermal insulation of the house: The thermal insulation of the house directly affects the heating effect of the biomass boiler. If the home is poorly insulated, a more powerful biomass boiler may be needed to meet heating needs.

Climate conditions: The heating effect of biomass boilers is also affected by local climate conditions. In colder climates, a more powerful biomass boiler may be needed to keep the home warm.

Fuel supply: Biomass boilers need to use biomass fuel, so they need a stable source of fuel supply. In some areas, obtaining biomass fuel may be easier, while in other areas it may take more time and effort to obtain.

Installation conditions: Installing a biomass boiler may require certain space and facilities, such as fuel storage facilities, chimneys, etc. Therefore, it is necessary to ensure that the house has suitable conditions for installing a biomass boiler.

In summary, biomass boilers can be an option for home heating, but they need to be evaluated and selected based on the specific house situation, climatic conditions, and personal needs. When choosing a biomass boiler for heating, it is best to consult a professional heating engineer or installation service provider to ensure the right model is selected and the correct installation is carried out.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler