Pharmaceutical Industry Boiler Selection Guide-The pharmaceutical industry places high demands on boiler performance, as drug manufacturing involves stringent hygiene, safety and quality standards, as well as the need to meet specialised production requirements. Boilers in the pharmaceutical industry must meet extremely high hygiene standards to ensure that pharmaceutical processes are not contaminated. In addition, pharmaceutical processes often require very precise temperature control to ensure the stability and quality of the reacting substances. Boilers must provide high purity steam to avoid the introduction of impurities or microorganisms into the pharmaceutical product. As a result, the specific requirements of the pharmaceutical industry place stringent demands on boiler performance to ensure hygiene, quality and compliance in the pharmaceutical manufacturing process.

Why choose a specialised boiler for the pharmaceutical industry?

The selection of specialised boilers for the pharmaceutical industry is crucial as they offer a number of key differences and advantages over general purpose boilers, emphasising their irreplaceability in pharmaceutical manufacturing.

Firstly, specialised boilers follow strict pharmaceutical industry hygiene and sanitation standards in terms of design and material selection, ensuring that internal surfaces are smooth and easy to clean and sterilise, thus reducing the risk of cross-contamination.

Secondly, pharmaceutical processes often require very precise temperature control to ensure the stability and quality of pharmaceutical products. Specialised boilers with higher levels of temperature control technology can provide highly accurate temperature management to meet these needs.

In addition, high purity steam is essential in pharmaceutical processes to avoid the introduction of impurities or micro-organisms into the pharmaceutical product. Dedicated boilers have special steam treatment and separation technologies to ensure the delivery of high purity steam.

Finally, pharmaceutical production requires flexibility, including the ability to start and stop production lines quickly. Speciality boilers are designed to have the ability to respond quickly to changes in production requirements.

In summary, the importance of specialised boilers in the pharmaceutical industry cannot be overstated, as their ability to meet the specific needs of high hygiene standards, precise temperature control, high steam purity and rapid responsiveness helps to ensure the quality, safety and compliance of pharmaceutical products. General purpose boilers struggle to meet these high demands, making specialised boilers indispensable in pharmaceutical manufacturing.

Key features of boilers for the pharmaceutical industry

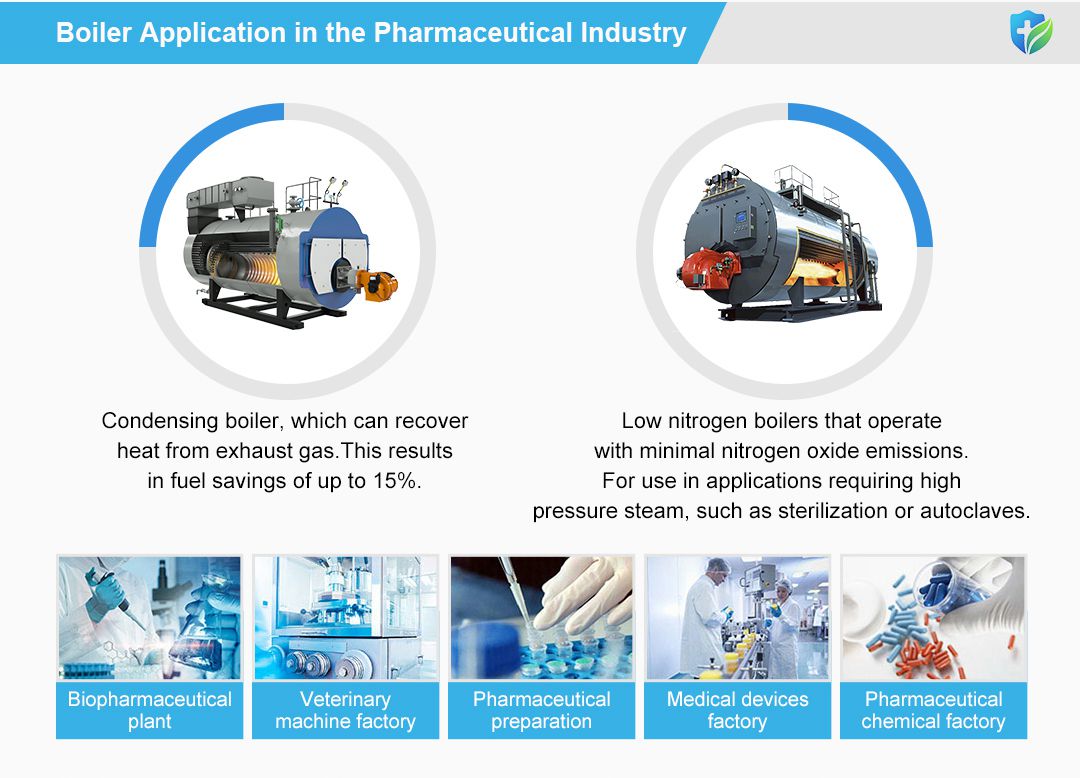

Boilers for the pharmaceutical industry have a number of key characteristics that must be met to fulfil specific needs, including temperature control and stability requirements, environmental and emissions standards, and safety and compliance requirements.

Firstly, pharmaceutical processes require a high degree of temperature control and stability. Even small temperature fluctuations can affect the stability of the reactants and the quality of the product. Therefore, boilers in the pharmaceutical industry must be able to provide highly accurate temperature control to ensure that reactions take place at the desired temperature conditions, thus ensuring product consistency and quality.

Secondly, the pharmaceutical industry has stringent requirements for environmental protection and emission control. Boilers must incorporate modern emission control technology to minimise harmful substances in air and wastewater discharges. Efficient exhaust treatment systems are necessary to ensure that emissions comply with regulatory and environmental standards.

Finally, safety and compliance are critical in pharmaceutical manufacturing. Boilers must meet a variety of safety standards to prevent accidents and protect personnel. In addition, the pharmaceutical industry needs to adhere to strict regulatory and compliance requirements, including quality control and drug registration regulations. Boilers must be designed and operated in accordance with these regulations to ensure that the medicines produced meet statutory requirements.

Taken together, boilers for the pharmaceutical industry must offer a high degree of expertise and reliability in terms of temperature control and stability, environmental and emission standards, and safety and compliance requirements. These key characteristics ensure the quality of pharmaceutical products, the sustainability of the manufacturing process and the protection of the environment.

Steam boilers vs hot water boilers: which is better for pharmaceutical production?

Steam boilers and hot water boilers both have their own characteristics and applications in different contexts, but in pharmaceutical production, steam boilers are usually more commonly used.

Steam boilers

Steam boilers

High Temperature, High Pressure Characteristics: Steam boilers are capable of generating high temperature, high pressure steam, which is often very useful in pharmaceutical processes where high temperatures are required for some reactions to take place to ensure product quality and reaction rates.

Heat transfer: Steam has good heat transfer properties and can effectively transfer heat to different parts of the production process to ensure the required temperature and pressure conditions.

Cleanliness: Steam is a relatively clean thermal medium, often free of impurities, which is important for pharmaceutical processes to avoid the introduction of contaminants into the product.

Versatility: Steam can be used for a variety of purposes, including heating, drying, cleaning and sterilisation, which increases its suitability for use in pharmaceutical production.

Hot Water Boilers

Low Temperature, Low Pressure Characteristics: Hot water boilers produce hot water rather than steam, often at lower temperatures and pressures. This is suitable for some pharmaceutical processes, especially reactions requiring low temperature conditions.

Energy efficiency: Hot water boilers can be more efficient in providing heat in some cases because they do not need to heat the water to the high temperatures required to produce steam.

Safety: Hot water boilers are often easier to manage in terms of operation and maintenance because they operate at lower pressures, which reduces some of the potential hazards.

In pharmaceutical manufacturing, steam boilers are often preferred because they are suitable for many processes that require high temperature and pressure conditions. However, the exact choice should depend on the specific process requirements and available resources. Sometimes, pharmaceutical plants may use both steam and hot water boilers to meet the needs of different processes. Regardless, safety, environmental friendliness and energy efficiency are always important considerations, and choosing the right type of boiler for pharmaceutical manufacturing is a critical step in ensuring product quality and compliance

Energy efficiency and cost considerations

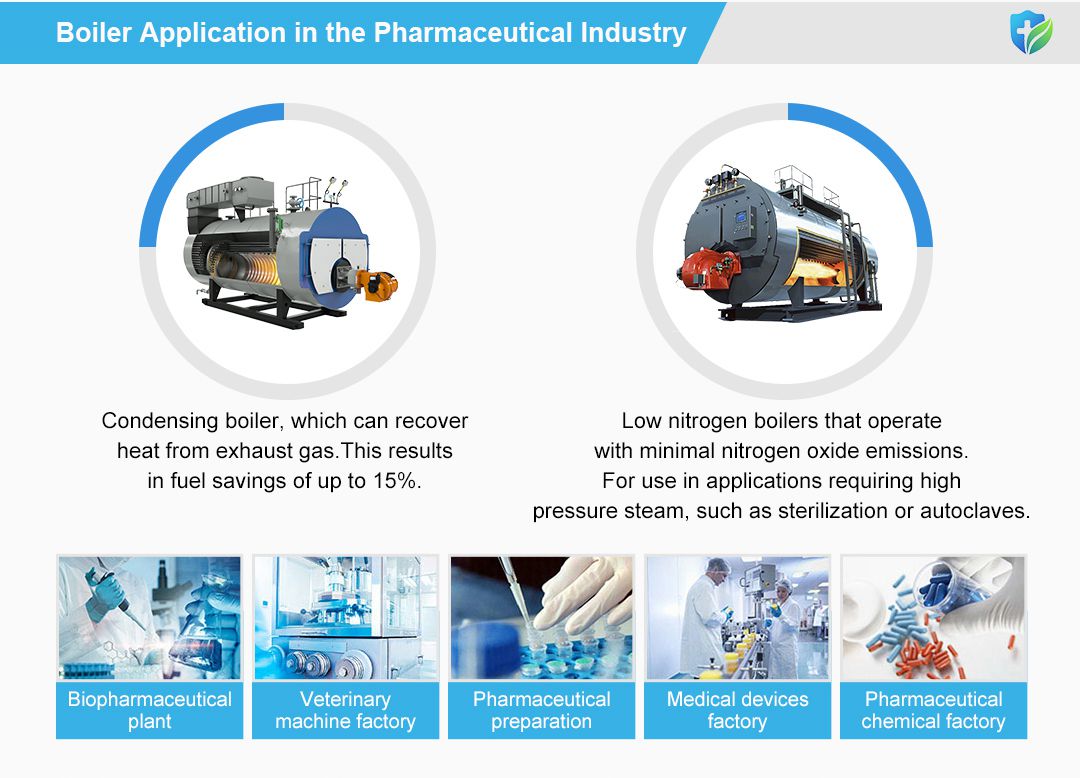

Energy efficiency and cost are key considerations in the pharmaceutical industry. Choosing a high-efficiency boiler can provide a variety of benefits, including lower energy costs, reduced environmental impact, increased productivity and sustainable production.

Reduced Energy Costs: High efficiency boilers are often able to convert fuel into heat more efficiently, thereby reducing operating costs. This is particularly important in the pharmaceutical industry, where energy consumption is often a significant portion of the manufacturing process.

Reduced environmental impact: High-efficiency boilers produce fewer emissions during the combustion process, helping to mitigate the negative environmental impact of pharmaceutical production and helping to comply with environmental regulations.

Improved productivity: Consistent heat and steam quality improves productivity and product quality, reducing production downtime and production failures.

Sustainable production: High-efficiency boilers help ensure a stable energy supply, supporting sustainable production and business continuity.

So how should boiler energy efficiency be considered? The following key performance indicators are commonly used to measure boiler energy efficiency:

1. Combustion efficiency: Combustion efficiency indicates the percentage of fuel that is efficiently converted into heat during combustion. Higher combustion efficiency means less wasted energy.

2. Thermal efficiency: Thermal efficiency is the ratio of heat energy generated by the boiler to the fuel input. Higher thermal efficiency means that more heat energy is utilised.

3. Waste Heat Recovery: Waste heat recovery systems reuse waste heat and improve overall heat utilisation.

4. Operational stability: Stability of boiler operation is also important for energy efficiency, as erratic operation can lead to wasted energy.

Taking these factors into account, along with regular monitoring and maintenance of the boiler, ensures that high-efficiency boilers are fully utilised in the pharmaceutical industry, reducing costs, minimising environmental impact and increasing productivity.

Impact of material selection for key boiler components on the pharmaceutical industry

In the pharmaceutical industry, the choice of materials for key boiler components has a significant impact on the performance, hygiene and maintainability of the equipment.

Boiler shells: Boiler shells can be made of high-strength, high-temperature resistant carbon steel or stainless steel with good corrosion resistance. Stainless steel is usually more suitable for the pharmaceutical industry as it does not release harmful substances into the production process.

Combustion chambers and flue/water pipes: These components are required to be used in high-temperature, high-pressure environments and are usually made of alloy steel or special stainless steel materials. These materials are able to withstand high temperatures, pressures and corrosion and ensure stable heat transfer.

Chimneys and venting systems: Chimneys are usually made of high temperature resistant stainless steel or special alloy steels. The materials used in the venting system must comply with environmental standards in order to avoid a negative impact on the environment.

Insulation: High-temperature insulation materials, such as aluminosilicate wool or high-temperature fibreglass, are often used for the insulation of boilers to ensure that the outer surface of the boiler remains relatively cool.

When selecting materials, the pharmaceutical industry needs to give special consideration to hygiene and the purity of the production process. Therefore, it is recommended to select materials that do not release harmful substances or particles to ensure product quality and hygiene standards. In addition, the choice of materials for boilers should comply with industry codes and regulations to meet health and safety requirements.

Safety standards and compliance requirements for boilers in the pharmaceutical industry

In the pharmaceutical industry, safety standards and compliance requirements for boilers are critical, as the manufacture of pharmaceutical products involves high hygiene and product quality requirements. The safety standards and compliance requirements for boilers in the pharmaceutical industry include the following:

1. Boilers should comply with relevant national standards and regulations, and can only be used after acceptance by a qualified department.

2. The operating parameters of the boiler should be controlled in strict accordance with the parameters of the equipment and should not exceed the specified safety range. During the operation of the boiler, the indicators should be checked regularly and records should be kept.

3. When abnormalities occur during boiler operation, the boiler operator should immediately stop the machine for maintenance and report to the boiler safety management department in a timely manner. For the occurrence of faults should be dealt with in a timely manner, and make a good record of the faults and processing measures to be organised.

To ensure boiler compliance with regulations, pharmaceutical companies usually need to:

Work with an experienced boiler manufacturer to select equipment that complies with regulations.

Conduct regular internal and external audits to ensure boiler compliance.

Follow pharmaceutical industry hygiene and quality standards to ensure the hygienic performance of the boiler.

Pharmaceutical companies should work with boiler manufacturers and engineers to ensure that the boiler meets regulations during the manufacturing process while ensuring product quality and hygiene.

Boiler maintenance and servicing

In the pharmaceutical industry, the proper functioning of boilers is critical, so regular maintenance and servicing procedures are required to ensure their efficiency, safety and hygiene.

CLEANING THE BOILER INTERIOR: Regularly clean the interior of the boiler, including the combustion chamber, flue/water pipes, heating surfaces and flue. Remove accumulated combustion debris, dirt and dust to ensure efficient heat transfer.

INSPECT AND REPLACE SEALS: Regularly inspect boiler seals, such as doors, holes and joints, to ensure their integrity and reliability. Replace damaged or deteriorated seals as necessary.

Check safety valves and pressure relief devices: Regularly check the operation of safety valves and pressure relief devices to ensure that they are releasing pressure properly when required.

CHECK WATER LEVELS AND PRESSURES: Regularly check boiler water levels and pressures to ensure they are within safe limits.

Regular maintenance and servicing can help to ensure that boilers in the pharmaceutical industry are functioning properly, efficiently and hygienically. Through regular maintenance, potential problems can be prevented and boiler reliability and performance can be improved to ensure product quality and safety.

Success story

A pharmaceutical company had been using an old boiler, resulting in high energy consumption and high operating costs. The company chose to upgrade to a high-efficiency gas-fired boiler with advanced combustion technology and an energy-saving control system. As a result, the company realised significant energy cost savings, while reducing carbon emissions and improving productivity.

Another pharmaceutical company paid particular attention to hygiene and compliance in their boiler selection. They chose a stainless steel boiler that complied with GMP and GB requirements to ensure product quality was not contaminated. This decision helped the company pass regulatory scrutiny while improving the sustainability of the manufacturing process.

Another pharmaceutical company focused on boiler safety and reliability. They chose a boiler with a multi-layer safety system, automatic shutdown features and remote monitoring. This decision helped the company avoid potential safety risks and reduce production interruptions.

These success stories highlight how the right boiler choice can positively impact the pharmaceutical industry. Different application scenarios require different types of boilers, so pharmaceutical companies need to select the right boiler solution based on their specific needs, hygiene requirements and production goals to get the best results.

Best practices and recommendations

Before selecting a boiler, gain an in-depth understanding of and adhere to the pharmaceutical industry's hygiene standards, GMP requirements and other compliance requirements. Select high-efficiency boilers with advanced combustion technology and energy-saving control systems to reduce energy costs and minimise carbon emissions. Select boilers with adjustable loads to accommodate different production needs and improve the flexibility of the production process. Boilers should be equipped with multi-layer safety systems, automatic shutdown functions and remote monitoring to ensure the safety of the production process. Look for boiler manufacturers with experience and expertise in the pharmaceutical industry to ensure that the selected boiler meets industry requirements. Consider the long-term implications of boiler selection, including environmental impact, and choose an environmentally friendly boiler to meet sustainable production goals.

Boiler selection should be holistic and need to consider factors such as hygiene performance, compliance, energy efficiency, safety and maintainability.

1. work with boiler manufacturers and engineers to ensure that the selected boiler meets specific needs and industry standards.

2. Train boiler operators to ensure they understand best practices and maintenance requirements.

3. Regularly assess boiler performance and perform maintenance and improvements to ensure long-term reliability and performance.

4. follow the latest pharmaceutical industry trends and technological developments to continually improve the performance and hygiene of pharmaceutical boilers.

Taking these best practices and recommendations into consideration will help pharmaceutical companies choose the right boiler solution to improve process sustainability, product quality and productivity.

To summarise

The selection of boilers for the pharmaceutical industry is critical to the success of the pharmaceutical industry. These boilers not only affect product quality and safety, but also have a profound impact on energy efficiency, environmental protection and cost control. Hygienic performance, compliance, energy efficiency and safety are key factors that must be prioritised when selecting a boiler. We therefore strongly recommend that pharmaceutical companies invest in high quality, hygiene compliant, energy efficient and safe boiler solutions.

The choice of a boiler for the pharmaceutical industry is a strategic investment that will provide lasting benefits for future success and sustainability. Don't hesitate to take action and purchase a high-quality boiler suitable for the pharmaceutical industry to ensure your pharmaceutical production is at its best.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler

Steam boilers

Steam boilers