What is Biomass?

Biomass is an organic material of plant and animal origin, which is a renewable energy source that can be used as an alternative to fossil fuels. Biomass has become important in global energy over the last few decades. It plays a vital role in addressing issues like climate change and pollution.

So what types of biomass are used in industrial boilers? There are many types. They include wood, farm waste, food waste, and special energy crops. We can convert these biomass materials into heat. We do this through combustion and other means. This heat provides the energy for various processes.

Biomass converts to energy in many ways. These include biochemical, thermochemical, and pyrolysis. In biochemical conversion, microorganisms or enzymes convert biomass into biofuels such as bioethanol. In contrast, thermochemical conversion involves processes like pyrolysis, gasification, or combustion. They convert biomass into liquid, gaseous, or solid fuels. Bio-pyrolysis, on the other hand, is a process that breaks down biomass into liquid fuels and biochar at high temperatures. These energy products can be used for many applications. These include power generation and heating and they provide key support for sustainable energy development.

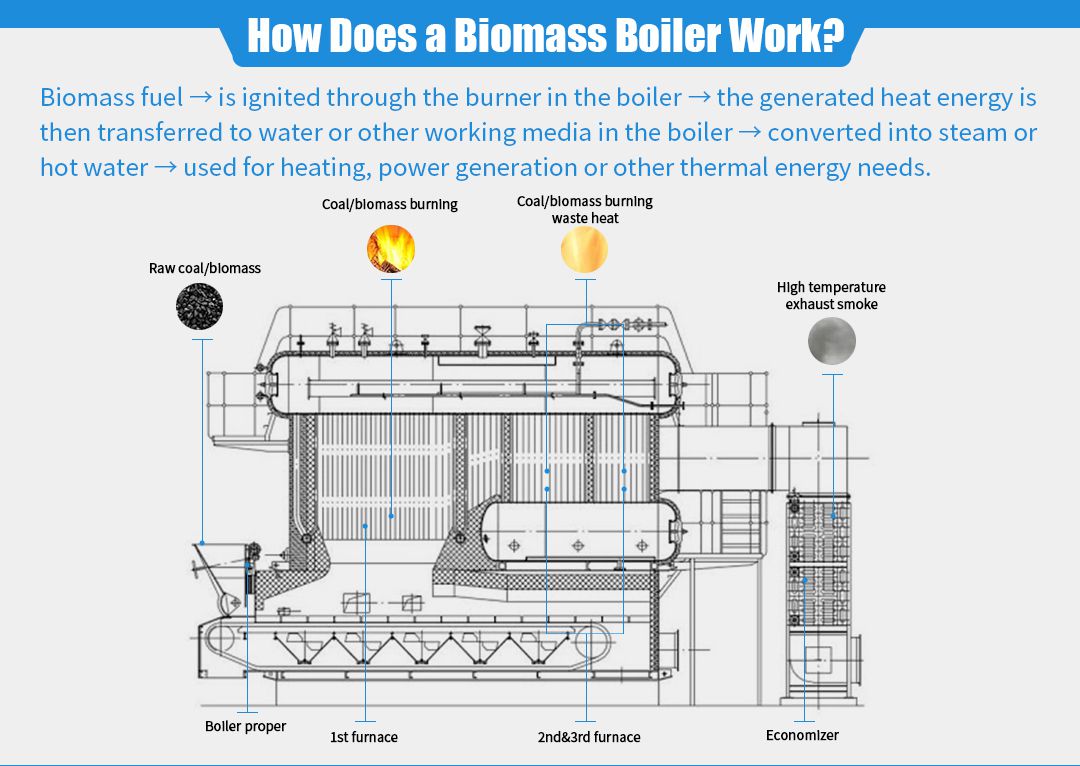

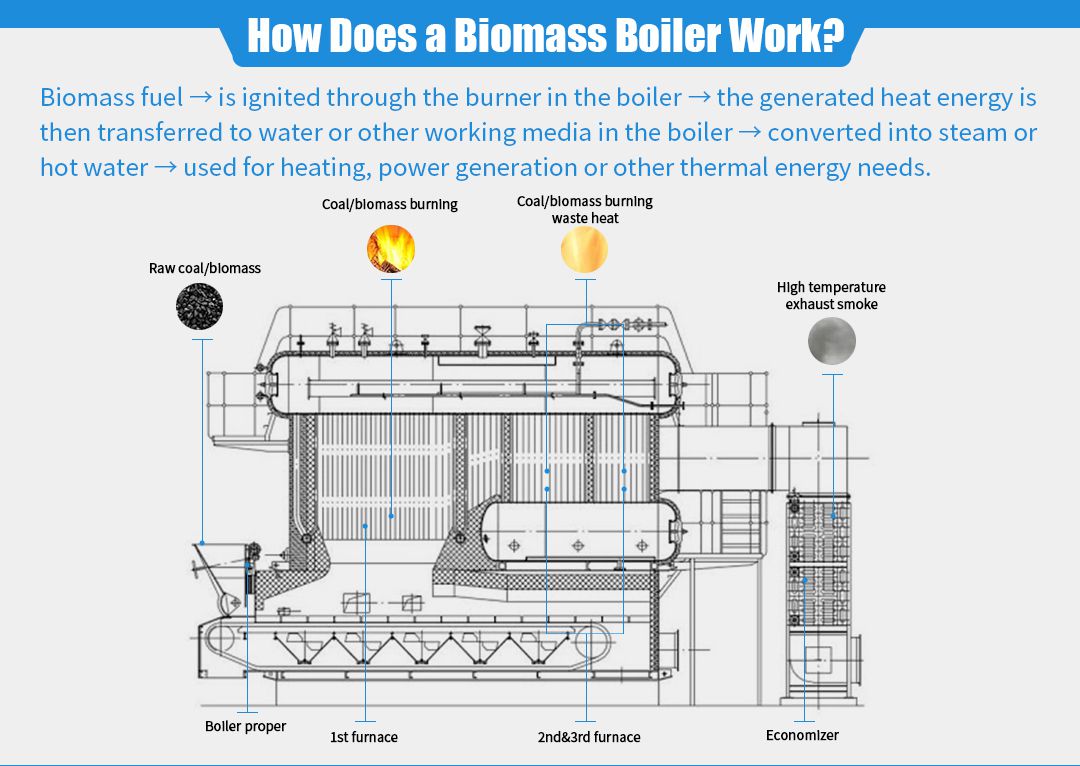

How Does a Biomass Boiler Work?

A biomass boiler is a thermal energy device that uses biomass as fuel. Its working principle is based on the combustion of biomass. Biomass fuels, like wood and crop residues, are burned in a boiler. The heat from the fire is then passed to water or other working medium. The medium is turned into steam or hot water. This can be used for heating, power, or other thermal energy needs.

How to operate a biomass boiler? There will generally be the following basic steps:

Fuel preparation: We mix biomass fuels, like wood chips and straw, according to certain ratios. We also prepare them to meet size requirements.

Fuel delivery: Fuel made from biomass is fed into the boiler's combustion chamber. This can be done automatically or manually.

Ignition and combustion: The biomass fuel ignites in the combustion chamber. We control the combustion process by adjusting the parameters. This ensures that the fuel fully burns.

Heat energy conversion: The heat from combustion heats water or other working medium in the boiler. This converts it into steam or hot water.

Heat output: The generated steam or hot water is piped to the place where heat is needed.

Compared with traditional fossil fuel boilers, biomass boilers have the following advantages:

Renewable energy: Biomass fuel comes from renewable resources, like agricultural and forestry wastes, and urban garbage. It has the trait of sustainable use.

Environmentally friendly: Burning biomass makes as much CO2 as plants absorb. So, it's seen as a relatively eco-friendly way to get energy.

Economical: The relatively low price of biomass fuels helps to reduce operating costs. In addition, biomass boilers can also achieve waste resource utilization, further improving economic efficiency.

Commonly used technologies for biomass boilers include:

Combustion control technology: Improve the combustion process by adjusting the parameters. This will raise efficiency and heat use.

Heat recovery technology: Boiler flue gas, ash, and other waste heat are used to improve energy use.

Automation control technology: We will use an advanced automation control system. It will make the boiler operate, monitor, and maintain itself. This will improve its stability and safety.

Environmental Benefits of Biomass in Boilers

Global climate change is increasingly serious. Protection of the environment is now a key issue for human survival and development. In this context, biomass as a renewable energy source is receiving more and more attention. One of the best is using biomass in industrial boilers. This has two benefits. It is good for the environment and can cut greenhouse gas emissions.

In many countries and regions, industrial boilers burn biomass. They see it as carbon-neutral. When trees or waste are used as fuel, there is no increase in CO2 emissions. On the contrary, a large amount of carbon dioxide is absorbed during the growth of the tree and stored inside the trunk in the form of organic matter. So, the carbon dioxide released from burning biomass as a boiler fuel was fixed and then released again by nature. It does not add to the overall emissions.

Also, biomass in boilers can greatly improve air quality. This is when compared to fossil fuels. Biomass is more natural or a by-product of regeneration. It has far fewer pollutants than fossil fuels.

Of course, when considering encouraging the use of biomass to combat global warming, we cannot ignore that it has its own limitations. First, acquiring and storing these resources uses a lot of energy and money. Second, their use is not yet universally recognized. Lastly, we need to improve the technology to use them better and cut emissions. But in any case, people believe that with science and technology progress and growing environmental awareness, the future of biomass as clean energy will be unstoppable.

Economic Benefits of Biomass in Boilers

Today, we pursue sustainable development and cut carbon emissions. Biomass, a renewable energy source, is getting more attention. In this context, the use of biomass in industrial boilers will have significant economic benefits.

The economic benefits of biomass boilers are mainly reflected in the following aspects:

First, biomass boilers use renewable biomass fuels, like crop residues and wood waste. These fuels are cheap. Using biomass boilers can cut energy costs. Biomass fuels have stable prices. They also have a clear cost advantage over time, compared to fossil fuels.

Also, the government provides incentives and subsidies for biomass. They strongly support the widespread use of biomass boilers. These incentives cut the cost of biomass boilers. They also grow related industries, like making, processing, and moving biomass fuels. This growth further boosts the economy.

In addition, the use of biomass boilers helps create jobs and boosts the local economy. Collecting, processing, and moving biomass fuels needs many workers. It provides lots of local jobs. Meanwhile, by buying biomass fuel locally, it can drive the growth of local agriculture, forestry, and related industries. This will bring new life to the local economy.

Finally, several industries can benefit from the adoption of biomass boilers. For example, the power and heat industries can use biomass boilers. They cut costs and clean up energy conversion. Agriculture and forestry can make extra money from selling biomass fuels. This also promotes the resourceful use of farm waste.

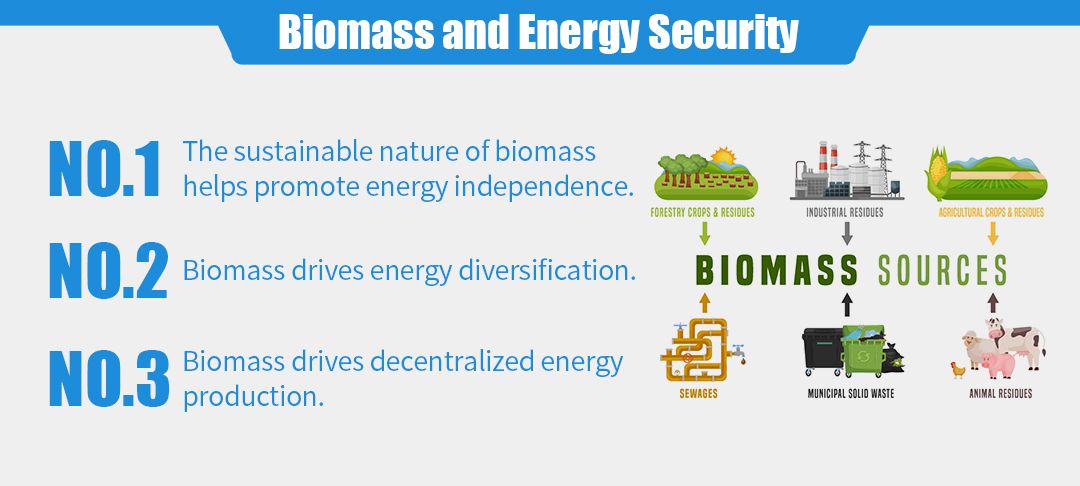

Biomass and Energy Security

Biomass has a strong link to energy security. It supports energy independence, diversification, and less reliance on imports.

Using biomass as a renewable energy source is sustainable. It helps with energy independence. We can reduce our reliance on outside energy and lower the risk of energy supply. We can do this by fully using local biomass resources, such as agricultural waste and forestry residues. This will enhance national energy security.

Biomass also plays an important role in promoting energy diversification. Biomass energy has unique advantages over traditional fossil energy sources. Its wide range of sources not only increases the reliability of energy supply but also reduces the risk of a single energy supply. We can diversify our energy mix by using biomass energy. This will make our energy supply more resilient and sustainable.

Biomass also plays an important role in decentralized energy production. Decentralized energy production offers more flexibility. It also offers more reliability than traditional centralized methods. Distributed energy equipment, like biomass boilers and gensets, can be flexibly configured to match demand. This allows for local energy production and use. This cuts the cost of energy distribution. It also makes energy use more efficient.Decentralized energy production can also boost local economies. It can increase jobs and make local economies more resilient.

Challenges and Considerations

Material boilers face many challenges. They must be considered in their application, especially in supply chain management, land use, biodiversity, material storage and handling, and regulatory compliance.

1. Supply chain management for consistent biomass sourcing

The stable operation of a biomass boiler depends on a stable and consistent supply of biomass fuel. Therefore, it is crucial to establish an effective supply chain management mechanism. However, biomass fuels are sourced from diverse and dispersed sources, which increases the difficulty of supply chain management. the EPCB boiler is designed with fuel diversity and adaptability in mind and is capable of handling multiple types of biomass fuels, which alleviates the pressure of supply chain management to a certain extent.

2. Impacts on land use and biodiversity

The collection and production of biomass fuels may affect land use and biodiversity. Large-scale biomass cultivation may lead to overexploitation of land resources and disruption of ecological balance.EPCB boiler emphasizes the use of sustainable biomass resources in its promotion, and encourages the use of renewable resources, such as agricultural wastes and forestry residues, in order to reduce the pressure on land resources.

3. Precautions for storage and handling of biomass materials

Biomass fuels are susceptible to moisture and deterioration, so the storage environment needs to be kept dry, ventilated, and protected from sources of ignition. In the process of handling, it is necessary to avoid crushing and contamination of the fuel.EPCB boiler provides a complete set of storage and handling solutions, including specialized storage facilities, drying equipment, and auxiliary equipment such as a crusher, to ensure the stable quality of biomass fuels and handling efficiency.

4. Regulatory and Compliance Issues for Biomass Boilers

The operation of biomass boilers needs to comply with relevant environmental and safety regulations. As the awareness of environmental protection increases, the emission standards and energy efficiency requirements for biomass boilers are also increasing.EPCB boilers are designed with full consideration of environmental protection and energy efficiency requirements, and advanced combustion technologies and emission control technologies are adopted to ensure that the boiler's emissions meet national standards.

Future Trends of Biomass Boilers

Concerns about carbon emissions and climate change are growing. The future trend of biomass boilers is clearly toward sustainability.

First, technology and efficiency drive biomass boiler development. Science and technology are improving biomass boilers. They are optimizing their design, manufacturing, and operation. This will improve their combustion and energy use. Biomass boilers can meet energy demand well. They also cut pollutant emissions and use energy better.

Secondly, biomass plays an important role in realizing renewable energy goals. Biomass boilers, as key equipment for biomass energy utilization, will play a more important role in the field of renewable energy. The government has introduced supportive policies to promote the market for biomass boilers. This supports the further development of the biomass energy industry.

Also, biomass boilers can easily work with other renewable energy sources. Renewable energy technologies continue to develop and improve. Biomass boilers can be combined with other renewable energy technologies. These include solar and wind energy. This forms a diverse energy supply system. This will improve the stability and reliability of energy. It will cut energy costs and promote the use of renewable energy.

In the next decade, technology will progress continuously. Markets will expand, too. This will further improve biomass boilers' performance and efficiency. It will also make their place in renewable energy more solid. At the same time, the biomass industry will also promote better technology and industry upgrades. It will make big contributions to the global shift to sustainable energy.

Conclusion

Using biomass as fuel in industrial boilers opens a new path. It's for energy use and environmental protection. Biomass energy is abundant and renewable. It is also clean and eco-friendly. It has low operating costs and is highly automated. They reduce dependence on fossil fuels and greenhouse gas emissions. They also promote the upgrade of energy structure and sustainable development.

EPCB boilers face severe challenges: the global energy crisis and climate change. They must constantly seek cleaner, more efficient, and sustainable energy solutions. Biomass energy is just such a choice with great potential. EPCB Boiler encourages the whole community to explore biomass. It is a sustainable energy source. They should also keep promoting the innovation and use of related technologies.

FAQ

What are the most common types of biomass in boilers?

The most common types of biomass found in boilers include wood waste, such as wood chips, and agricultural waste.

Wood wastes, such as wood chips, are a common type of biomass fuel. They are usually made from materials such as waste from wood processing or sawdust. Wood chips have stable combustion performance and high calorific value, which meets environmental requirements.

Agricultural waste, such as straw, is waste produced in agricultural production. It can be used as biomass fuel after it is processed. Straw has good combustion performance and high calorific value, and at the same time, it can make full use of agricultural waste resources and support rural economic development.

While food waste and specialized energy crops can also be used as biomass fuels, they are relatively less common in boilers.

Are biomass boilers suitable for residential use?

Yes, biomass boilers use biomass fuels that produce relatively low carbon dioxide emissions when burned, helping to mitigate climate change. In addition, the price of biomass resources is relatively low, and using a biomass boiler can effectively reduce production costs, making it an affordable option for home users.

To ensure the safe and efficient operation of a biomass boiler, proper installation and maintenance is essential. With the correct installation and maintenance, a biomass boiler is a sustainable energy solution for residential use.

Is biomass really carbon neutral?

Biomass is not the same as being carbon neutral, although it has some carbon neutral potential.

Biomass absorbs carbon dioxide from the atmosphere as it grows, but then emits carbon dioxide during energy conversion. From this perspective, the carbon emissions and carbon uptake of biomass are essentially equal, and can therefore be considered a zero-carbon energy source. However, carbon emissions from biomass are not completely avoided. Improper disposal of waste biomass can also reduce the vegetative cover of the land, leading to a reduction in carbon sequestration and thus a disguised increase in carbon emissions.

What are the costs associated with installing a biomass boiler?

The cost of installing a biomass boiler can be affected by several factors, including the type and size of the boiler required, the conditions of the installation site, and the demand for heat. In general, the initial installation cost of a biomass boiler may be somewhat higher than a traditional coal or oil-fired boiler, primarily because biomass boilers require special equipment and systems to handle biomass fuels.

Despite the high initial cost, biomass boilers typically have lower operating costs. This is since biomass fuels are relatively inexpensive and renewable, and the waste produced by biomass boilers during combustion can often be used as fertilizer or for other purposes, helping to reduce subsequent cleanup and disposal costs.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler