Maintaining a biomass boiler is essential to ensure its efficiency, safety, and longevity. Biomass systems play an important role in sustainable energy solutions by converting organic materials into heat. Like any other complex machine. Its optimal functioning depends on regular, specific maintenance.

Understanding the basics of biomass boiler operation is key. It can help prevent costly downtime and keep the system running smoothly. It also helps with the maintenance the system needs. This article will cover the basics of maintaining your biomass boiler. It will discuss daily, weekly, monthly, and yearly tasks. It will also address common issues and decide when to seek professional help. By sticking to a regular maintenance program, you can greatly improve your boiler's performance. This will cut costs and make the boiler last longer. So, it's a wise investment for any business that relies on biomass energy.

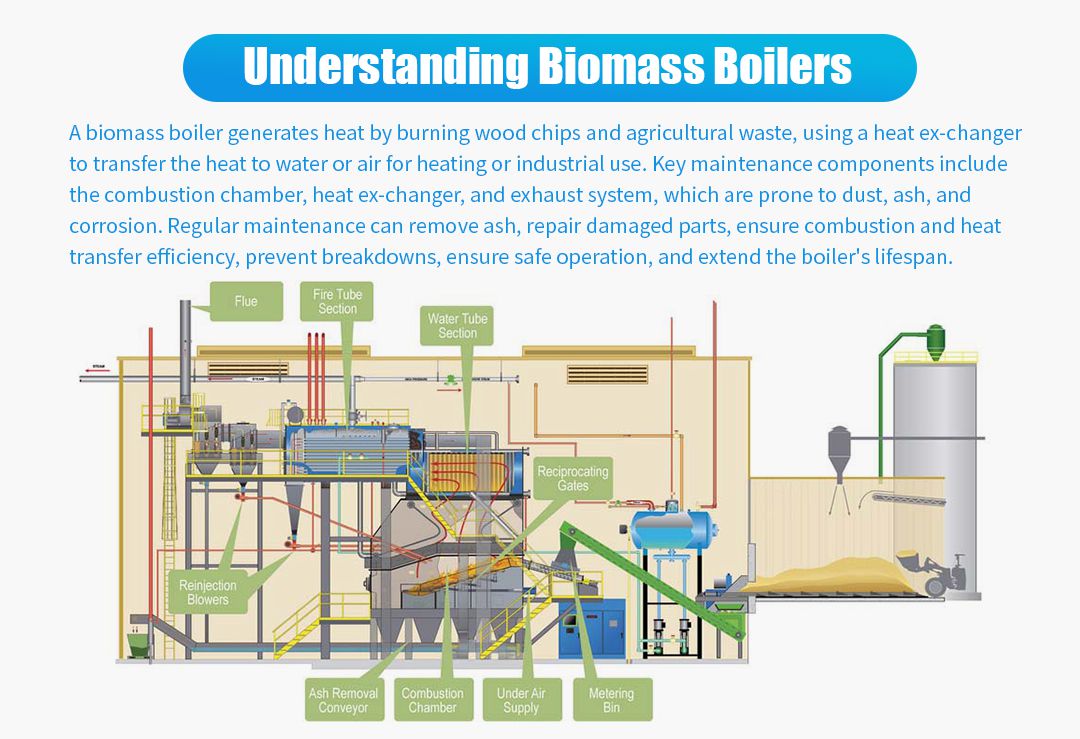

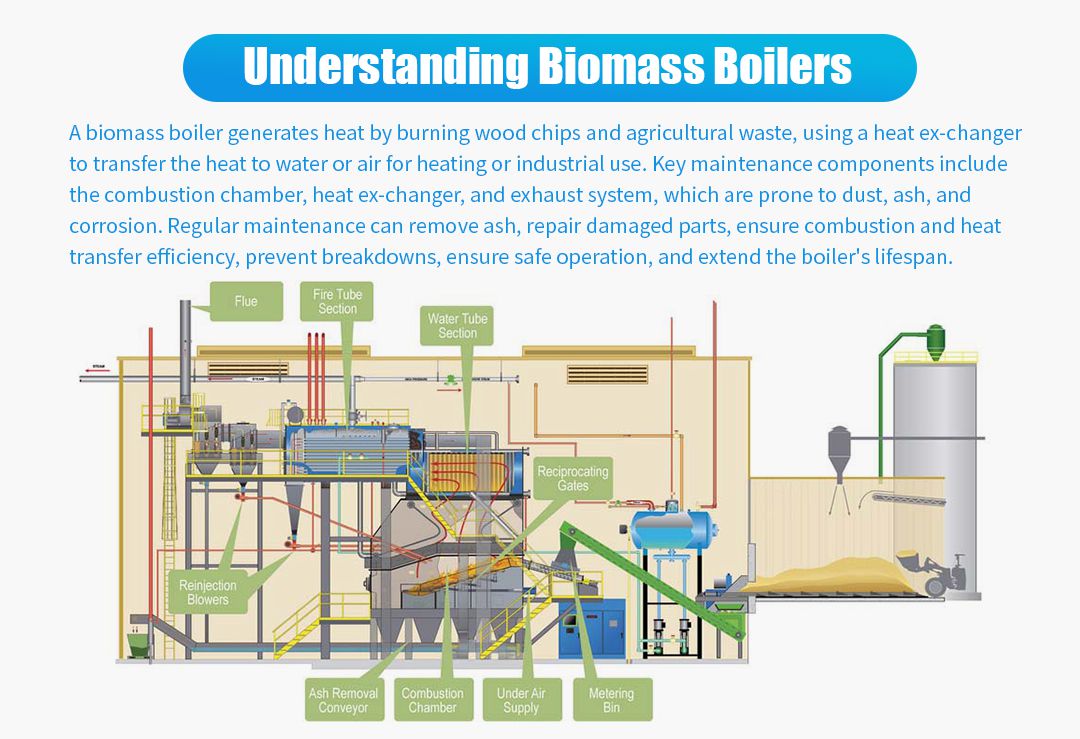

Understanding Biomass Boilers

Biomass boilers generate heat by burning organic materials such as wood pellets or chips. This process involves multiple components, each of which requires regular attention to maintain optimal performance. Key components include the heat exchanger, combustion chamber, and fuel supply system.

The heat exchanger transfers the heat generated by burning the biomass to the heating system. The combustion chamber is where the fuel is burned and the fuel supply system ensures a continuous supply of biomass to the boiler. Each component must be maintained in good condition to ensure efficient heat production and minimize environmental impact.

Regular maintenance tasks are essential to keep the boiler efficient and safe. For example, cleaning the heat exchanger prevents soot buildup, which can impede heat transfer and reduce efficiency. Similarly, checking combustion chambers for signs of wear and tear can prevent premature failure. In addition, monitoring the fuel supply system ensures reliable, efficient operation.

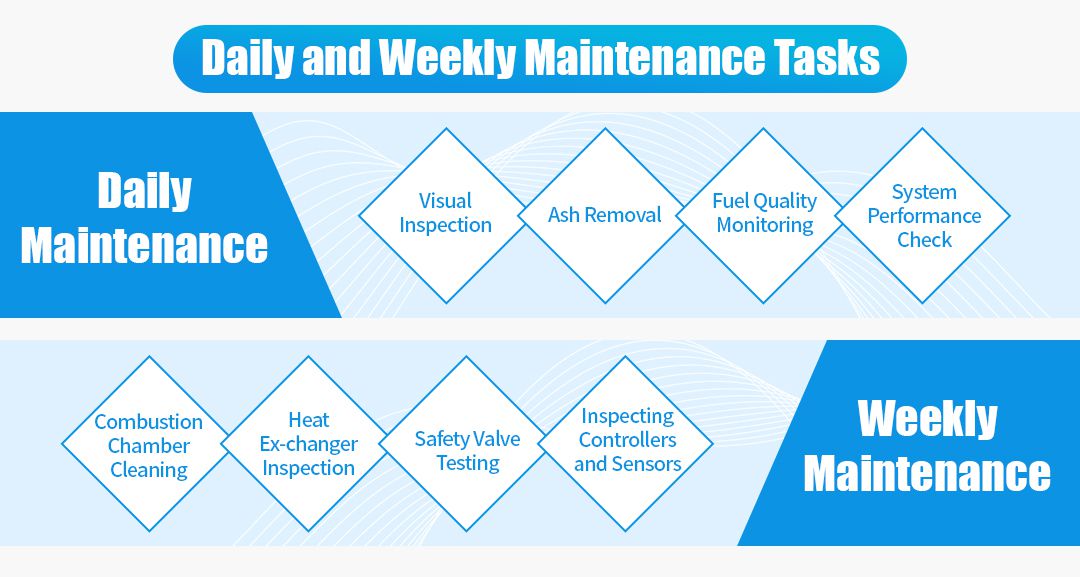

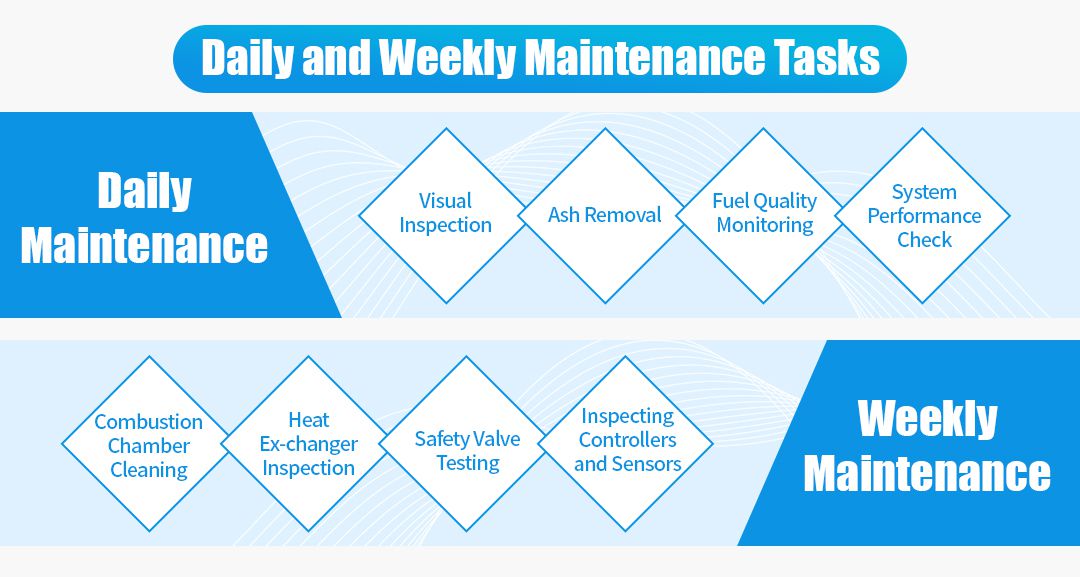

Daily and Weekly Maintenance Tasks

Daily and weekly maintenance of your biomass boiler involves routine inspections and minor cleaning tasks to ensure the system is running smoothly. These ongoing activities are critical for the early detection of problems and for maintaining operational efficiency.

Daily Maintenance

Visual Inspection: begin with a visual inspection of the boiler and its surroundings. Check for any signs of leaks, unusual noise, or smoke.

Ash Removal: Remove ash from the combustion chamber and ash bin to prevent buildup, which can reduce combustion efficiency.

Fuel Quality Monitoring: Check the quality of the biomass fuel. Make sure it is dry and free of contaminants, as poor-quality fuel can affect performance and cause damage.

System performance check: Monitor system performance indicators such as temperature and pressure. Any deviation from the normal range should be investigated immediately.

Weekly maintenance

Combustion Chamber Cleaning: The combustion chamber is cleaned more thoroughly than routine ash removal. This includes removing any unburned fuel and soot deposits.

Heat Exchanger Inspection: Check the heat exchanger for signs of corrosion or blockage. If necessary, clean to maintain effective heat transfer.

Safety Valve Test: Test the safety valve to ensure it is working properly. This is critical to prevent overpressurization situations.

Check controls and sensors: Verify that all controls and sensors are functioning properly. This includes checking the calibration of thermostats and pressure gauges.

Do these daily and weekly tasks. Add them to your routine. They will keep your biomass boiler in good order. These tasks can stop small problems from becoming big. They also extend your boiler's life and keep it efficient.

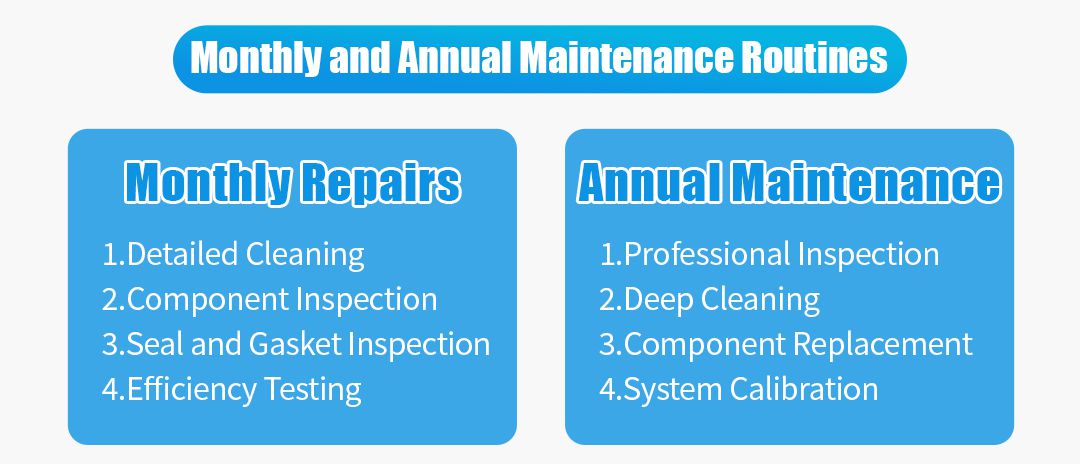

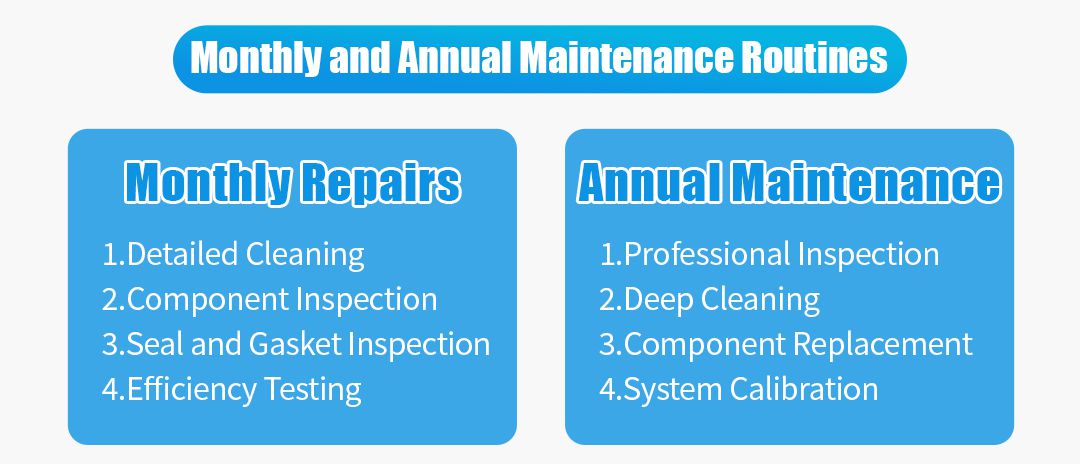

Monthly and Annual Maintenance Routines

Monthly and annual maintenance routines are critical to the long-term health and performance of your biomass boiler. These tasks go beyond daily and weekly inspections and involve more detailed checks and adjustments.

Monthly Maintenance

Detailed Cleaning: Thorough cleaning of boiler components, including heat exchangers, combustion chambers, and flue. This prevents soot buildup, which can reduce efficiency.

Component Inspection: Thoroughly inspect all major components. Look for signs of wear, such as cracks or corrosion, and replace any damaged parts.

Seal and Gasket Inspection: Check seals and gaskets for signs of wear or leaks. Replace them as needed to ensure proper sealing and prevent air or water leaks.

Efficiency Test: Perform an efficiency test to measure the performance of your boiler. Adjust settings as needed to maintain optimal efficiency.

Annual Maintenance

Professional Inspection: Schedule a professional inspection of the entire system. A certified technician can identify potential problems that may not be apparent during a routine inspection.

Deep Cleaning: Perform a thorough cleaning of the boiler, including the heat exchanger, combustion chamber, and all flues. This helps maintain peak efficiency and extends the life of the boiler.

Component Replacement: Replace any components that are showing obvious signs of wear or are nearing the end of their expected life. This may include components such as the fuel supply system or the combustion chamber.

System Calibration: Calibrate all controls and safety devices to ensure they are functioning properly. This includes pressure gauges, thermostats, and safety valves.

By doing these monthly and yearly maintenance tasks, you can avoid expensive repairs. They will also ensure that your biomass boiler runs well and safely. Regular maintenance not only extends the life of your boiler but also improves its performance, making it a valuable asset to your business.

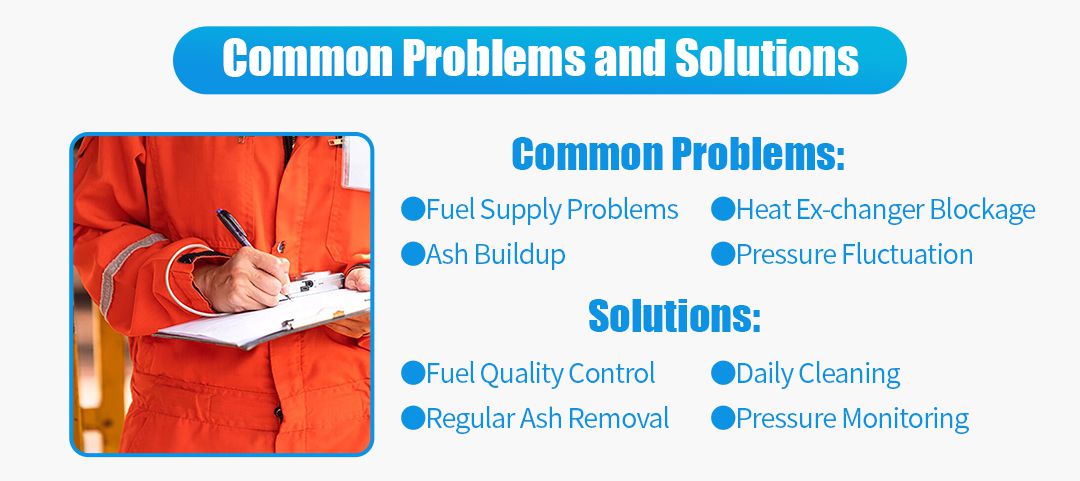

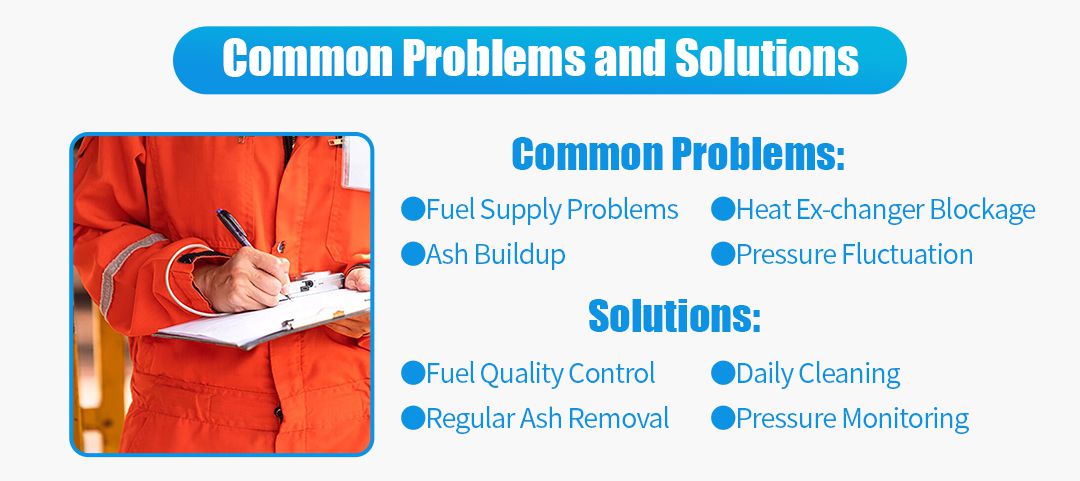

Common Problems and Solutions

Despite regular maintenance, biomass boilers can still experience operational problems. Understanding common problems and their solutions can help you resolve them promptly and maintain efficient operations.

Common Problems

Fuel supply issues: Inconsistent fuel supply or poor biomass quality can lead to incomplete combustion and reduced efficiency.

Ash buildup: Excessive ash buildup can impede airflow and impair combustion, leading to reduced efficiency and potential damage.

Clogged heat exchangers: Soot and ash can clog heat exchangers, reducing heat transfer and increasing fuel consumption.

Pressure fluctuations: inconsistent system pressures can indicate a leak or safety valve malfunction and require immediate attention.

Solution

Fuel Quality Control: Ensure a consistent supply of high-quality biomass fuel. Store fuel in a dry, clean environment to prevent contamination and moisture buildup.

Regular ash removal: Implement a strict ash removal program. If possible, equip the boiler with an automatic ash removal system to minimize manual cleaning.

Routine cleaning: Clean heat exchangers regularly to prevent soot buildup. Use proper cleaning tools and techniques to avoid damaging components.

Pressure monitoring: Monitor system pressure closely. If it fluctuates, check for leaks and check the condition of the safety valves. Replace faulty components promptly.

While many maintenance tasks can be handled in-house, certain issues require specialized knowledge. Seek professional help in the following cases:

-Abnormal noise or fumes persist despite routine inspection and cleaning.

-Pressure continues to fluctuate after basic troubleshooting.

-There is a significant drop in efficiency and a potential hidden problem.

-Signs of severe wear or damage to major components.

By understanding and addressing these common problems, you can ensure the smooth operation of your biomass boiler and avoid costly repairs. Regular maintenance and timely intervention are key to maintaining optimal performance. Choosing a professional boiler manufacturer, such as EPCB Boilers, will provide you with more reliable service and support to ensure your boiler system runs efficiently and safely.

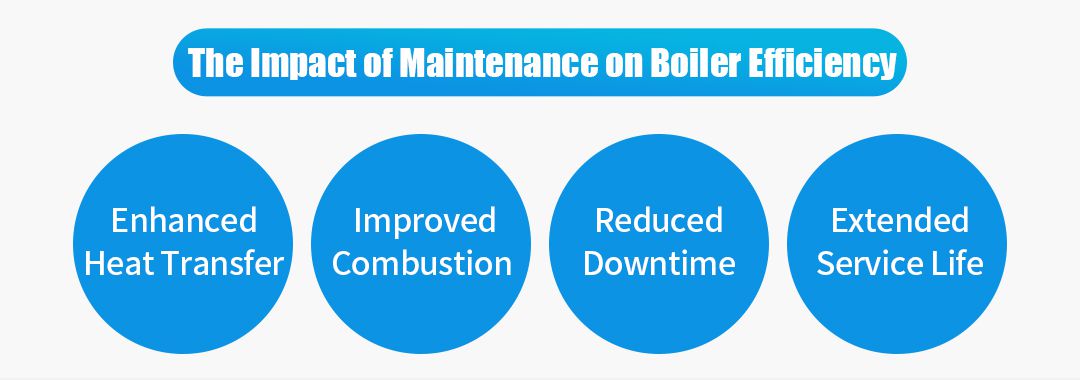

The Impact of Maintenance on Boiler Efficiency

Regular maintenance has a profound effect on the efficiency of a biomass boiler. Ongoing maintenance not only ensures optimum performance but also plays a vital role in saving energy and reducing costs.

Enhanced heat transfer: A clean heat exchanger contributes to efficient heat transfer, reducing fuel consumption and improving overall efficiency.

Improved combustion: Regular cleaning and fuel quality control ensure complete combustion, maximizing heat output and minimizing waste.

Reduced downtime: Preventive maintenance minimizes the risk of unplanned breakdowns, ensuring continuous operation and reducing downtime costs.

Longer service life: Well-maintained boilers have a longer service life, providing a better return on investment and reducing the need for premature replacement.

Case Study

A manufacturing plant implemented a rigorous maintenance program for their biomass boilers that included daily, weekly, and monthly tasks. As a result, they saw a 15% improvement in efficiency within the first six months. This improvement translated into significant fuel savings and a significant reduction in operating costs.

Tips for Maintaining Optimal Performance

Follow manufacturer's guidelines: Follow the maintenance recommendations provided by the boiler manufacturer.

Keep detailed records: Keep a log of all maintenance activities, including dates, tasks performed, and any problems found. This helps track performance and plan for future maintenance.

Use quality replacement parts: When replacing components, use manufacturer-approved, high-quality parts to ensure compatibility and reliability.

Professional Services & DIY Maintenance

When it comes to biomass boiler maintenance, choosing between professional service and DIY tasks can be challenging. Both approaches have their benefits, and understanding them can help you make an informed decision.

DIY Maintenance

Certain maintenance tasks can be handled in-house by trained personnel, saving costs and providing convenience.

Routine inspections: Daily and weekly visual inspections, dusting, and basic cleaning can often be performed in-house.

Simple repairs: Minor repairs, such as replacing seals or gaskets, can be done in-house with the right tools and training.

Efficiency monitoring: Regularly checking system performance indicators and adjusting settings can help maintain efficiency.

Specialized Services

Hiring a professional to perform more complex tasks ensures that your biomass boiler is thoroughly inspected and professionally treated.

Comprehensive inspections: Professionals can perform detailed inspections to uncover potential problems that may not be apparent during routine checks.

Advanced repairs: Complex repairs, such as replacing major components or resolving major system malfunctions, require specialized knowledge.

System calibration: A professional can accurately calibrate controls and safety equipment to ensure optimal performance and compliance with safety standards.

There are many benefits to hiring a professional for boiler maintenance. First, professionally trained technicians have a wealth of knowledge and experience that allows them to handle complex maintenance tasks and repairs, ensuring that boiler systems are in optimal condition. Second, professionals follow strict safety protocols, which greatly reduces the risk of accidents during maintenance, thus ensuring the safety of personnel and equipment. Finally, entrusting boiler maintenance to professionals gives you peace of mind, relying on professional services that allow you to focus on your core business without worrying about routine maintenance and potential problems with your equipment.

When choosing between DIY maintenance and professional services, consider the complexity of the task and the expertise required. For routine inspections and minor repairs, DIY maintenance can be cost-effective. However, for comprehensive inspections and complex repairs, professional services are essential.

Long-term care and upgrades

Long-term maintenance and strategic upgrades are critical to maintaining the performance and efficiency of your biomass boiler. This ensures that your system remains up-to-date with the latest advances and continues to meet your energy needs.

When to consider upgrading?

When performance drops: If you notice a significant drop in efficiency or an increase in operating costs, it may be time to upgrade certain components.

When technology needs to advance: Keeping up with new technology can provide opportunities for improved efficiency and sustainability.

When components are retired: Replace components that are nearing the end of their useful life to prevent unexpected failures.

Long-term maintenance program

Regular inspections: Implement a long-term maintenance program that includes regular inspections and cleaning of critical components.

Budget allocation: Allocate a budget for ongoing maintenance and potential upgrades. This ensures you are prepared for any necessary repairs or improvements.

Training and development: Invest in training for your maintenance staff to keep them up to date with best practices and new technologies.

To make your biomass boiler last longer, adopting new technologies and energy efficiency upgrades is key. Aligning maintenance practices with sustainability goals not only reduces your carbon footprint but also makes a positive contribution to the environment. By adopting a long-term approach to maintenance and upgrades, you can ensure that your biomass boiler will remain a valuable asset for years to come.

Conclusion

Regular maintenance is essential for optimal performance and longevity of your biomass boiler. By following daily, weekly, monthly, and annual maintenance routines, you can avoid costly repairs, improve efficiency, and extend the life of your equipment. Investing in professional services for complex tasks ensures thorough inspections and expert treatment, while routine inspections and minor repairs can be managed in-house. In addition, long-term maintenance programs and strategic upgrades can future-proof your biomass boiler to keep it in line with the environment, adopting the latest technological advances and sustainability goals.

As a full-service boiler system solutions provider that integrates boiler design, boiler manufacturing, boiler installation, and boiler maintenance, EPCB provides professional service and support to ensure that your boiler system operates at its best. By working with EPCB, you can develop and implement a comprehensive regular maintenance program to ensure your biomass boiler runs efficiently and reliably, providing your business with a sustainable and cost-effective energy solution. In short, consistent and proactive maintenance is essential to maximize the benefits of biomass energy, and EPCB's professional services will help you achieve this.

FAQ

How often should a biomass boiler be maintained?

Regular maintenance intervals vary depending on the type and use of the biomass boiler. In general, daily and weekly visual inspections and cleaning tasks are recommended. More detailed monthly and annual inspections should be performed to ensure optimal performance. Refer to the boiler manufacturer's guide for specific recommendations.

What are the signs that a biomass boiler needs maintenance?

Warning signs that a biomass boiler may need maintenance include:

-Abnormal noise or vibration during operation

-Visible smoke or soot buildup around the boiler

-Decreased efficiency or increased fuel consumption

-Inconsistent system performance, such as temperature or pressure fluctuations

Can poor maintenance lead to increased operating costs?

Yes, neglecting regular maintenance can significantly increase operating costs. Problems such as soot buildup, inefficient combustion, and worn components can reduce boiler efficiency, leading to higher fuel consumption and potential damage. Regular maintenance helps prevent these problems and ensures that the boiler operates at peak performance.

What safety precautions should I take when maintaining my biomass boiler?

Safety is vital during boiler maintenance. Always follow the manufacturer's guidelines and ensure that the system is shut down and cooled before starting any task. Use appropriate personal protective equipment and never attempt to repair or replace any component without proper training and knowledge.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler