Click to Jump to What You Want to Know Quickly.

1. Save equipment cost

2. Save in transportation cost

3.Save installation cost

4.Save operating costs

5.Environmental cost savings

6.EPCB's guarantees

EPCB new steam generator helps you save production costs in many ways:

1. Save equipment cost

Integrated design saves burner and many auxiliary machines.

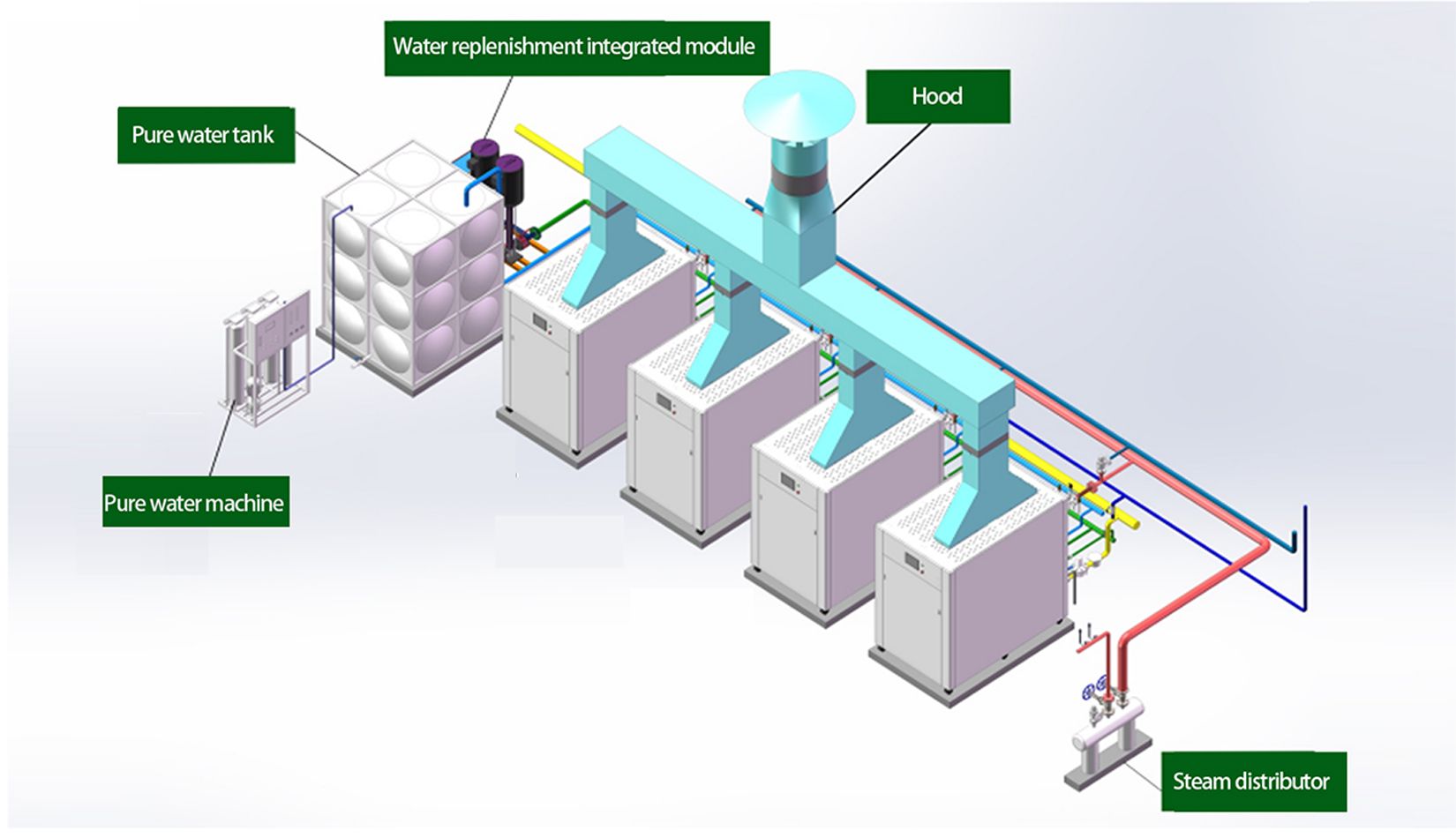

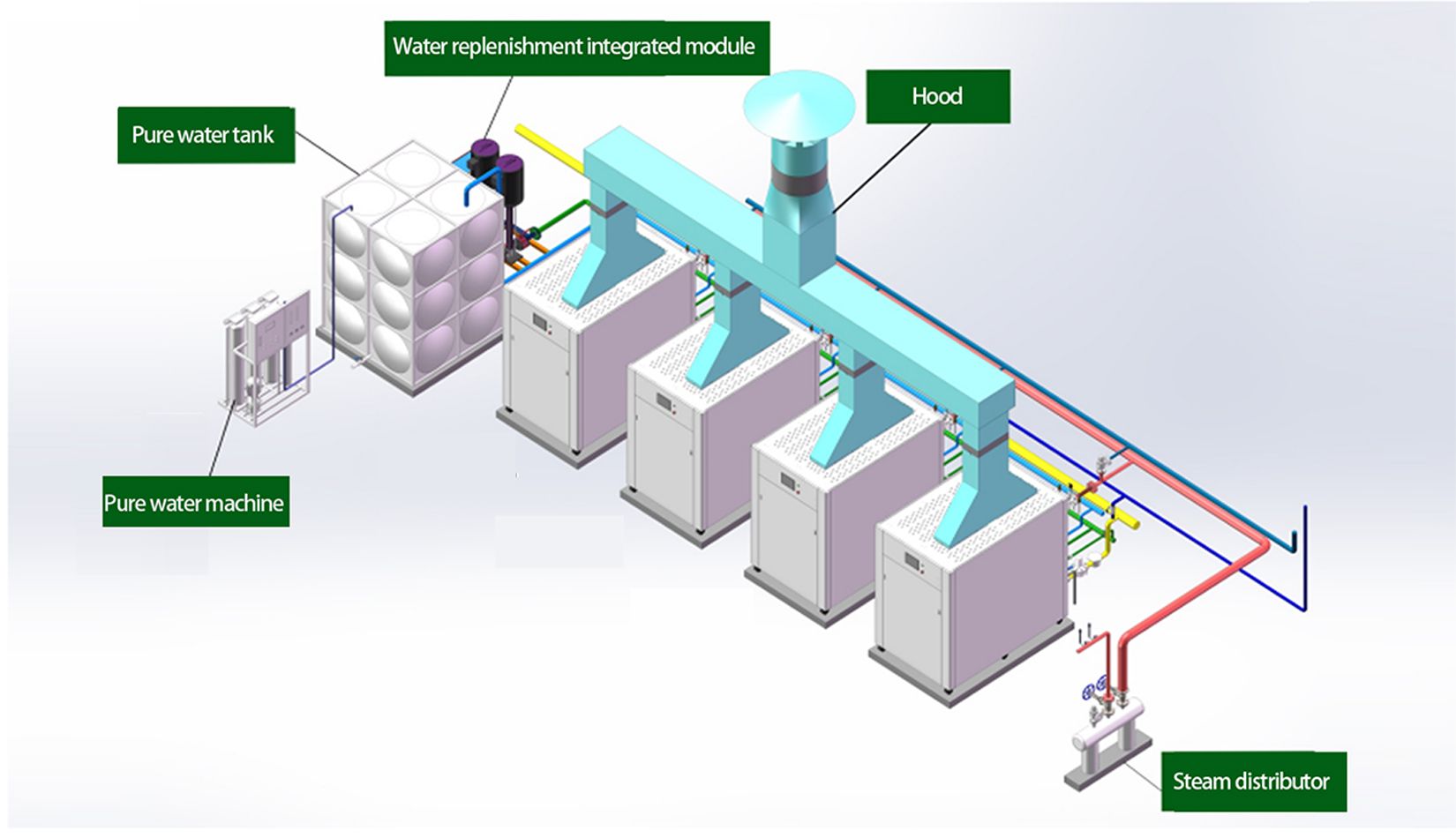

The steam source equipment system consists of circulating pump, upper heat exchanger, lower heat exchanger, combustion chamber, steam water separator, control system, measurement feedback equipment, pipeline and other accessories.

l water vapor separator: high quality steam is separated, the effective steam is more than 97%, and the steam water content is controlled within 3%.

l circulating pump: the separated hot water is recycled without waste and energy saving.

l upper heat exchanger: secondary utilization of flue gas heat, full absorption of waste heat and use of alloy steel.

l lower heat exchanger: open flame direct combustion, high-density fin heat exchange, alloy steel.

l combustion chamber: special fire exhaust is used to avoid electronic control, with high stability and stainless steel.

l control system: chip imported from Japan, CPU electric control, igniter, temperature control sensor, etc., independently developed and produced.

l condensation system: the waste heat in the flue gas is recycled again, which greatly improves the thermal efficiency.

2. Save in transportation cost

Small size, ordinary containers can hold 5 one ton boilers;

There are few auxiliary machines, only water treatment and chimney are required;

3.Save installation cost

With integrated design and soft connection, it is easy to install to the user's site.

4.Save operating costs

① High thermal efficiency and fuel saving

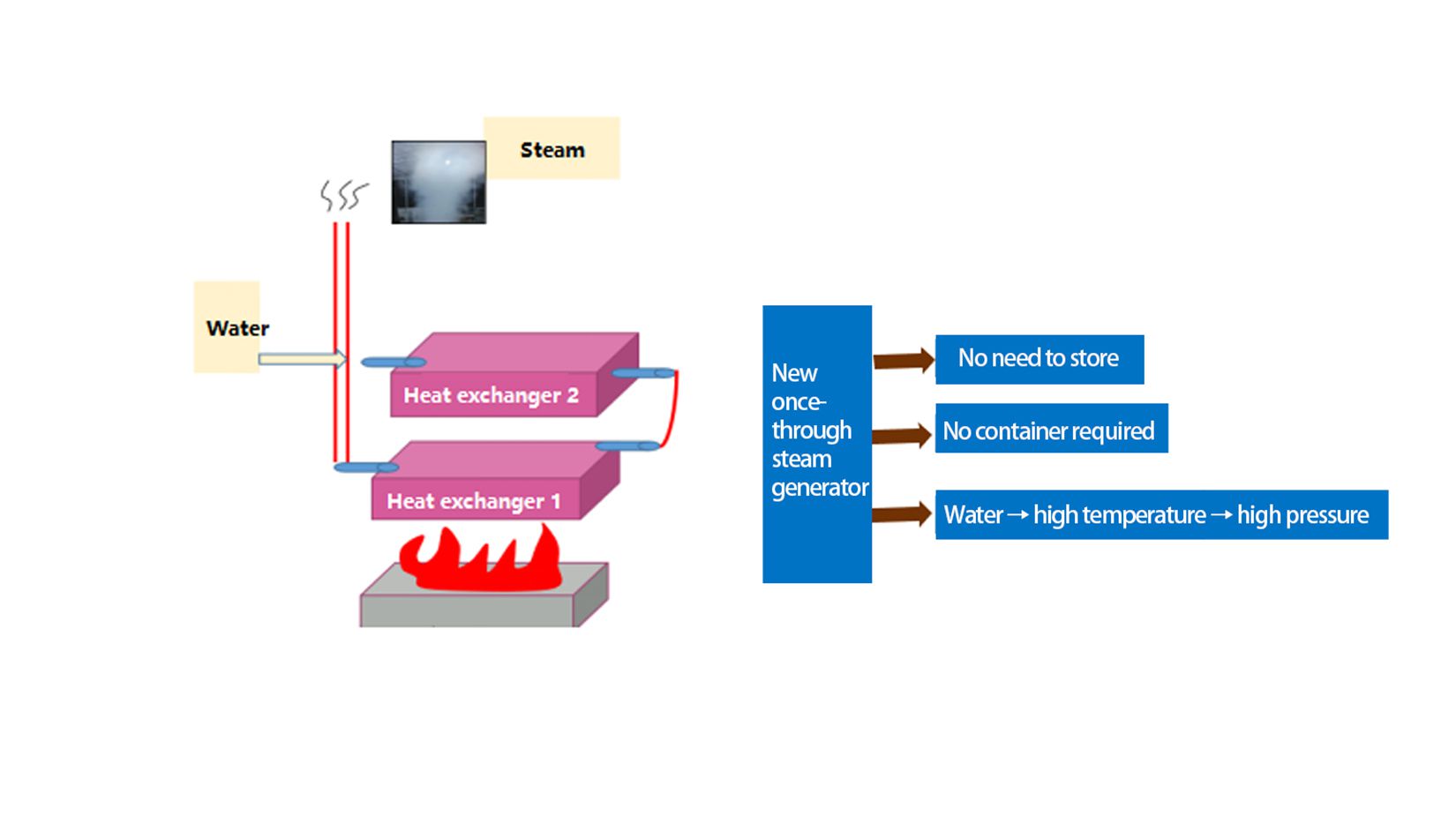

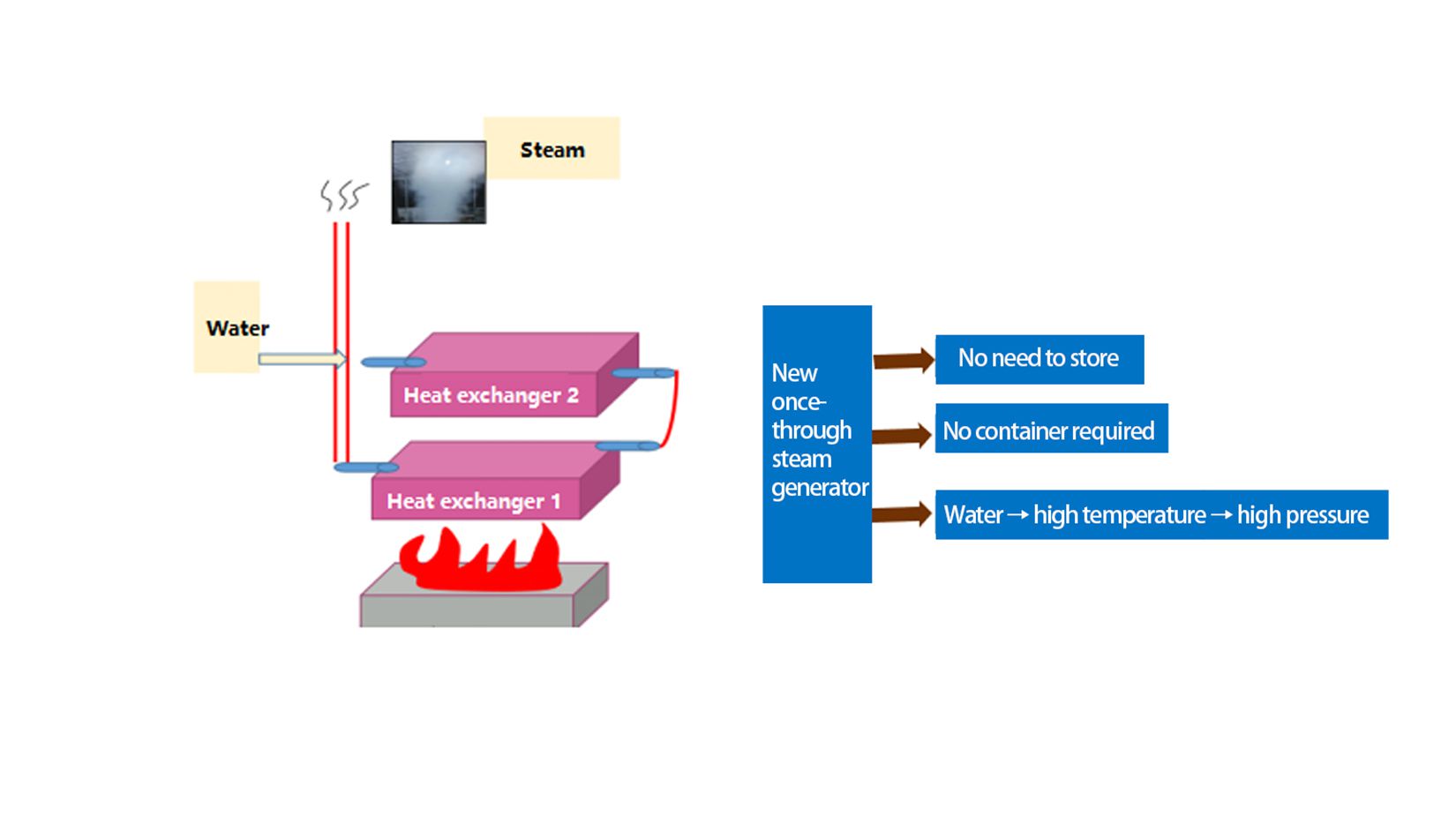

The steam source subverts the working principle and process of the traditional steam equipment "water storage heating water boiling steam generation". The steam source uses the self-developed new "once through steam generation technology" to convert water into steam as soon as the tap water flows through the combustion chamber, thus reducing the process and links of "water storage heating water boiling" of traditional steam equipment, and the whole process from Startup to steam generation is completed in 5 seconds.

The new type of alloy steel finned heat exchanger has the advantages of fast heat absorption, more heat absorption, high heat conversion efficiency, safe use, environmental protection, durability, convenience, energy conservation and environmental protection, and is widely used.

② Simple operation and labor saving

PLC electric control system, one screen can operate the whole system, the interface is simple, easy to understand and easy to use.

③Low failure rate and maintenance saving

All stainless steel, patented technology operation, design service life of 15 years.

5.Environmental cost savings

Ultra low nitrogen emission without additional treatment of tail gas.

Support 24-hour monitoring, NOx < 30g / m3, SO2 < 10g / m3, full evaporation.

EPCB can provide you with the most suitable products and continuous high-quality steam on the premise of ensuring safety.

EPCB can make three guarantees:

1. Ensure safety

Six fold safety protection: water cut-off (low water pressure) protection, fan abnormal protection, accidental flameout protection, overtemperature protection, overvoltage protection, power failure protection, high reliability and safety, and there will never be explosion risk.

Water cut-off (low water pressure) protection: automatic shutdown when there is no water or the water pressure is too low, which protects the equipment from dry burning.

Fan abnormal protection: fan failure will lead to internal temperature rise and automatic shutdown of the machine. Its function is overtemperature protection.

Accidental flameout protection: flameout automatically closes the solenoid valve, and the machine is protected and automatically shut down, which is the function of preventing gas leakage.

Overtemperature protection: sensing the scale of the heat exchanger to protect in advance and prevent dry burning.

Overvoltage protection: the overvoltage switch senses the signal and stops automatically.

Power failure protection: the gas solenoid valve is closed, and its function is also to prevent gas leakage.

2. Ensure working well

1. Cross flow steam generation technology - steam generation process of traditional cooking equipment: water storage - heating - water boiling - steam generation. Kailuoxin steam source uses the "cross flow steam generation technology" to generate steam as soon as the tap water flows through the heat exchanger, so as to realize steam generation within 5 seconds after startup without preheating, which greatly reduces the use cost of fuel. The steam boiler needs to pass through the pressure vessel to form steam pressure before it can produce high-temperature steam, and the steam source directly produces high-temperature steam. There is no need for the pressure vessel to form steam pressure at all.

2. Continuous steam transmission technology - central water supply and central heating. Traditional steam generating equipment or steam boiler realizes periodic water supply or heating by periodically segmented steam heating to make the water storage temperature reach the predetermined standard. The steam source uses the "steam continuous transmission technology" to make the steam continuously and quickly transmit, heat and store water almost without loss, so as to realize continuous and uninterrupted supply.

3. Low steam consumption transmission technology - realize almost zero heat loss in the process of steam transmission, so as to maintain a relatively continuous and stable water temperature in central water supply and central heating.

4. Intelligent frequency conversion technology - according to the change of steam consumption and the trend of pressure and temperature rise and fall, the system automatically stops and starts the module, and intelligently converts the frequency to the balance of heat energy supply and demand, so as to truly supply energy on demand, accurately supply energy and avoid waste!

5. Modular management technology - the steam source adopts modular design and is standby for each other. The equipment power can be adjusted according to the demand at any time to completely solve the problem of big horse pulling trolley. The equipment is small in size and can be installed in a distributed and centralized manner.

3. Ensure suitability

Our business team will first understand your real needs and select the most suitable equipment model for you according to your needs;Moreover, our scheme design is one-to-one. We design a complete set of steam supply scheme completely according to your local situation and the current situation and demand of the factory, and can ensure that our scheme is the best design.

You must also be worried about the after-sales problems when purchasing equipment. We have also taken your concerns into account. Therefore, we have two after-sales support to ensure that you can use our products smoothly.

1. Technical support

We have a professional technical team to solve all your questions online 24 hours a day, and we all have the ability to solve technical problems in a short time

2. Maintenance support

Some vulnerable parts are included in the factory

After sales service centers around the world

Free maintenance during warranty period

Lifelong maintenance

EPCB, your private boiler system expert!