Industrial steam boilers play a vital role in many industries, including chemical industry, food processing, energy production, textile printing and dyeing, etc. They provide necessary heat energy for the production process and ensure the efficient operation of industrial processes.

Industrial steam boiler is a kind of equipment that generates steam by burning fuel (such as natural gas, coal, oil or biomass) or by electric heating. Its main function is to heat water to high temperature and high pressure to generate steam to supply the heat energy demand in industrial production. Steam plays a vital role in many processes, such as heating, driving machinery, disinfection and sterilization, to ensure the efficient operation of industrial processes. Therefore, industrial steam boilers play a vital role in many industries, including chemical industry, food processing, energy production, textile printing and dyeing, etc.

However, when purchasing steam boilers, enterprises often pay attention to its cost composition and the economy of long-term operation. There are many factors that affect the cost of industrial steam boilers, including boiler type, capacity, fuel type, installation and maintenance costs. As a leading industrial boiler supplier, EPCB Boiler is committed to providing customers with efficient and reliable steam boiler solutions. By ensuring the high energy efficiency and advanced technology of products, we can help customers improve production efficiency and return on investment while controlling operating costs.

Key Factors Affecting the Cost of Industrial Steam Boiler

With the improvement of enterprise's requirements for energy efficiency and environmental protection, choosing a suitable steam boiler not only affects production efficiency, but also directly affects operating costs. Therefore, it is an important task for enterprise decision makers and engineers to understand the key factors affecting the cost of industrial steam boilers. The type, capacity and working pressure of the boiler, the type of fuel, the cost of installation and maintenance, and the energy-saving effect of the boiler are all important variables that directly affect its economy. It is particularly important to understand and master these key factors.

Boiler type

Different types of industrial steam boilers have different structures and operating principles, so the cost difference is significant. The main types include:

Gas-fired steam boilers: Generally speaking, the initial investment of gas-fired boilers is relatively high, but their operating costs are relatively low, especially in areas where gas prices are relatively stable. Gas-fired boilers usually have high thermal efficiency and low emissions.

Electric steam boiler: the purchase cost and installation cost of electric boiler are usually high, but in the process of operation, its energy efficiency is very high, which is suitable for areas with low electricity price. In addition, the maintenance cost of electric boilers is low because they have no complicated combustion system.

Coal-fired steam boilers: Relatively low fuel costs make coal boilers still competitive in some areas. However, incomplete combustion of coal will produce higher emissions, which may lead to additional environmental protection costs.

Biomass-fired steam boiler: This boiler uses organic materials as fuel. Although its initial investment is high, it can reduce the fuel cost in long-term use, especially suitable for areas where a large number of agricultural wastes are used.

Boiler capacity and pressure

The output capacity and working pressure of the boiler directly affect the cost;

Boiler capacity: The larger the capacity of the boiler, the lower the cost of unit steam production, but the overall investment will also increase. In addition, too large or too small boilers may reduce efficiency and increase unnecessary expenses.

Working pressure: High-pressure boiler has higher thermal efficiency and greater output capacity, but due to the complexity of its design and manufacturing requirements, the initial investment will increase. At the same time, the maintenance and safe operation costs of high-pressure boilers are also high.

Fuel type

The types of fuels and their market prices directly affect the operating costs of boilers:

Natural gas: relatively cheap and clean, it is the first choice fuel for many industries, and its operating cost is usually low. However, it is affected by market price fluctuations.

Coal: It is often the lowest-priced fuel, but its combustion efficiency is relatively low, and its environmental protection cost is high, which may lead to additional treatment costs.

Biomass: The cost of biomass fuel depends on the availability of raw materials, which is usually lower in some specific areas, but the transportation and treatment costs may be higher than other fuels.

Oil: Although the energy density of fuel oil is high, its price fluctuates greatly, and in the long run, environmental protection regulations may increase operating costs.

Installation and maintenance costs

Installation cost: The complexity of boiler installation process will directly affect the cost. Larger and more complicated boilers need longer installation time and more labor and materials, which will increase the initial investment.

Maintenance and repair costs: The maintenance costs of different types of boilers vary greatly. In general, the maintenance of gas and electric boilers is relatively simple and the cost is relatively low, while the maintenance cost of coal boilers is relatively high because of the need to clean the flue and the inside of the boilers regularly. High efficiency boilers are usually more compact in design and easy to maintain.

Energy saving effect

Energy-saving characteristics of high-efficiency boilers significantly reduce long-term operating costs;

Thermal efficiency: The thermal efficiency of high-efficiency boilers can reach more than 90%, which can save quite a lot of money on fuel consumption compared with traditional low-efficiency boilers. Under long-term operation, this saving can significantly reduce the overall operating costs.

Heat recovery technology: some high-efficiency boilers are equipped with heat recovery devices, which can convert waste heat into usable heat energy and further improve energy efficiency.

Reduce emissions: High-efficiency boilers can also reduce harmful emissions caused by insufficient fuel combustion and reduce environmental governance costs.

Boiler Solution Provided by EPCB Boiler

Brand introduction

EPCB Boiler is a leading industrial boiler manufacturer in the world, focusing on providing efficient and energy-saving boiler solutions. With years of industry experience and technological innovation, the company is committed to meeting the needs of global customers for industrial steam, hot water and heat transfer oil boilers. EPCB Boiler products are widely used in food processing, chemical industry, textile, medicine, heating and other industries, and have won the trust of customers with excellent quality, stable performance and efficient energy-saving technology.

Product line

EPCB Boiler has a rich product line covering all kinds of industrial boilers to meet the needs of different enterprises. Whether it is a gas-fired boiler with high efficiency and energy saving, a coal-fired boiler with low cost, an environmentally-friendly biomass boiler and a pollution-free electric heating boiler, EPCB Boiler can provide the best solution.

Steam boiler

Gas-fired steam boiler: It adopts advanced combustion technology and optimized design of thermal efficiency, with stable operation and low emission, and is widely used in industries with high requirements for environmental protection.

Coal-fired steam boiler: it is suitable for enterprises with low fuel cost and high demand for steam, and adopts advanced coal combustion technology to improve combustion efficiency and reduce pollution emissions.

Biomass steam boiler: using renewable biomass fuel, such as sawdust, straw, etc., which is green and environmentally friendly and has low operating cost.

Electric heating steam boiler: it is heated by electric energy, which is pollution-free and noise-free. It is suitable for industries with high requirements for environmental protection, such as food and pharmacy.

Hot water boiler

Gas-fired hot water boiler: suitable for heating, hotels, schools and other places, with the characteristics of high efficiency, energy saving and low nitrogen emission.

Coal-fired hot water boiler: it is suitable for industries with large demand for hot water and stable fuel supply. The combustion system is optimized and the thermal efficiency is improved.

Biomass hot water boiler: environmental protection and energy saving, suitable for agriculture, animal husbandry and rural heating.

Heat transfer oil boiler

Gas-fired heat transfer oil boiler: suitable for fine chemical industry, food processing, building materials and other industries, providing stable high-temperature heat transfer oil heating.

Coal-fired heat transfer oil boiler: The operating cost is low, and it is suitable for industrial applications that require high-temperature heat energy.

Biomass heat transfer oil boiler: environmental protection and energy saving, suitable for enterprises with requirements for renewable energy utilization.

Customized services

EPCB Boiler knows that different industries have different needs for boilers, so it provides all-round customized boiler solutions to ensure customers get the best energy efficiency and economic benefits.

The team of engineers communicated with customers in depth, analyzed the requirements of steam pressure, temperature, fuel type and application scenarios, and then formulated the optimal scheme and selected the appropriate boiler model and system configuration. Design low-emission boilers, such as low-nitrogen combustion technology and flue gas waste heat recovery, in combination with environmental protection standards in various regions to ensure energy conservation and environmental protection.

Installation and debugging: provide professional installation guidance and debugging services to ensure efficient and safe operation of boiler system.

After-sales support: 7*24 hours technical support, regular maintenance and training services to ensure the long-term stable operation of customers' boilers.

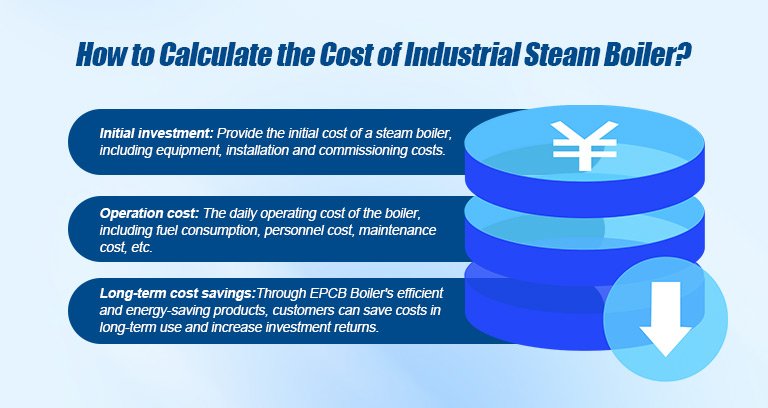

How to Calculate the Cost of Industrial Steam Boiler?

Initial investment

The initial cost of purchasing a steam boiler includes equipment purchase cost, installation and debugging cost. Different models and specifications of boilers have different prices, and the total investment cost will also be affected by the installation of pipelines, control systems and other auxiliary equipment.

Boiler body: the price of equipment varies with different models and configurations.

Installation cost: including infrastructure, pipeline installation, electrical connection, etc.

Commissioning cost: the cost of testing and acceptance to ensure the normal operation of the boiler.

Operating costs

The daily operation cost of boiler mainly includes fuel consumption, electricity cost, personnel salary, maintenance and overhaul cost, etc.

Fuel cost: It accounts for most of the boiler operation cost, and the price and combustion efficiency of different fuels (such as natural gas, coal, biomass, etc.) will directly affect the operation cost.

Labor cost: wages and training expenses of boiler operators.

Maintenance cost: regular maintenance, replacement of parts, cleaning of boilers, etc.

Long-term cost savings

EPCB Boiler is committed to providing high-efficiency and energy-saving boiler products, helping customers to reduce long-term operating costs by optimizing the combustion system, improving thermal efficiency and reducing energy waste.

Efficient combustion technology: reduce fuel consumption and improve boiler thermal efficiency.

Intelligent control system: optimize operation and reduce unnecessary energy loss.

Environmental protection design: reduce emissions, avoid environmental fines and improve corporate image.

In the end, customers can get higher return on investment and realize long-term economic benefits through efficient boiler system.

Advantages and Cost-effectiveness Analysis of EPCB Boiler

High efficiency and low cost

EPCB boiler is committed to providing a perfect balance between high efficiency and low operating cost by adopting advanced technology. In the process of boiler design and manufacture, the company uses optimized combustion technology, efficient heat exchange system and intelligent control platform to ensure that the boiler can maintain high thermal efficiency while minimizing energy consumption. Whether it is gas-fired, coal-fired or biomass boilers, EPCB can provide boiler solutions with excellent performance and low operating cost according to different customer needs. In this way, customers can not only enjoy efficient production energy efficiency, but also reduce fuel costs and maintenance costs and achieve long-term economic benefits.

Energy conservation and environmental protection

EPCB boiler pays attention to energy saving and environmental protection, especially in the context of increasingly strict environmental protection regulations, the company has always implemented the concept of green energy saving in product design. Through low-nitrogen combustion technology, flue gas waste heat recovery system and efficient combustion optimization, EPCB boiler has greatly reduced energy consumption and reduced harmful gas emissions, which meets many global environmental protection standards. For example, EPCB's low-nitrogen combustion technology can effectively reduce the emission of nitrogen oxides (NOx), help enterprises meet strict environmental protection requirements, reduce environmental pollution and support sustainable development. Through these technologies, EPCB boilers not only help customers reduce energy costs, but also contribute to environmental protection.

Customer Cases

EPCB boilers have successfully helped customers optimize costs and improve production efficiency in many industries. Here are some typical customer cases:

Food processing enterprises: A food processing factory successfully reduced energy consumption by more than 20% after choosing the gas-fired steam boiler of EPCB. Through the application of energy-saving technology, the enterprise not only recovered its initial investment in just one year, but also improved its production efficiency by 15%. In addition, the low nitrogen emission design of the boiler helped the enterprise successfully pass the examination of the environmental protection department, avoiding possible fines and rectification costs.

Chemical Plant: A chemical enterprise adopted EPCB's biomass steam boiler and used renewable biomass fuel to replace traditional coal, which significantly reduced the fuel cost. At the same time, the CO emission has been reduced by 25%, which is in line with the increasingly strict environmental protection regulations in the world. Through this change, enterprises not only saved a lot of fuel expenses, but also improved the green certification of production, obtained government subsidies, and further reduced operating costs.

Conclusion

It is the key to reduce the cost and improve the production efficiency to review the factors affecting the cost of industrial steam boilers and select the appropriate boiler suppliers. With its excellent technology and customized services, EPCB Boiler helps customers effectively reduce initial investment and long-term operating costs, optimize energy use and improve the overall efficiency of enterprises. By choosing EPCB boiler, you will not only reduce operating expenses, but also enhance the market competitiveness of enterprises.

If you want to know more details about industrial steam boilers, or get customized quotations according to your business needs, please contact EPCB Boiler immediately. Our professional team will provide you with tailor-made boiler solutions to help you improve production efficiency, reduce operating costs and achieve green and sustainable development.

FAQ

Q1: What is the cost of the industrial steam boiler?

The cost varies with boiler type, capacity, fuel and other factors. Please contact EPCB Boiler for specific quotation.

Q2: What is the price range of EPCB boilers?

EPCB provides a variety of boilers, the price ranges from tens of thousands of yuan to millions of yuan, which need to be customized according to the demand.

Q3: How to choose a steam boiler suitable for my enterprise?

A3: Production demand, fuel supply and environmental protection policies should be considered, and EPCB can provide professional selection guidance.

Q4: How to reduce the operation cost through EPCB boiler?

A4: EPCB boiler adopts efficient heat exchange, intelligent control and environmental protection combustion technology, which can significantly reduce fuel and maintenance costs and improve overall income.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler