In industrial production, thermal oil boilers have become an indispensable heat source in fields such as chemical processing, pharmaceuticals, and food production. With their highly efficient heat transfer performance and low operating pressure, thermal oil boilers provide stable high-temperature support for complex production processes. However, when equipment malfunctions or efficiency declines, the entire production line may face the risk of shutdown, leading to costly downtime and financial losses. Therefore, efficient after-sales service is the key to ensuring the long life and stable operation of thermal oil boilers.

To help businesses maximize the lifespan and productivity of their equipment, it is essential to understand the key components of after-sales service for thermal oil boilers. Next, we will explore in detail how comprehensive after-sales support ensures that your equipment remains in optimal working condition at all times.

The Importance of After-Sales Service for Thermal Oil Boilers

Thermal oil boilers play a critical role in industries such as chemical processing, pharmaceuticals, textiles, and food production. Unlike water or steam boilers, thermal oil boilers can provide high-temperature heat at lower pressures, making them an ideal choice for many processes that require stable and precise heat control. Their efficient heat transfer capabilities make them central to production operations, and any downtime or malfunction can result in production interruptions and costly delays. Therefore, maintaining the efficient and continuous operation of thermal oil boilers is essential for industrial productivity and product quality.

Effective after-sales service is key to ensuring the long-term healthy operation of thermal oil boilers. Due to the complexity of thermal oil boilers and their demanding operating environments, regular maintenance, timely troubleshooting, and the supply of spare parts are especially important. Robust after-sales service can significantly extend the boiler’s lifespan, ensuring that the equipment remains highly efficient throughout its lifecycle, ultimately bringing customers greater returns on investment (ROI). In addition, after-sales services can help clients reduce fuel consumption, lower the risk of malfunctions, and improve the overall reliability of the system through regular maintenance and energy efficiency optimization, ensuring uninterrupted production.

Moreover, excellent after-sales service providers offer professional training to the client’s operational teams, ensuring they can operate and maintain the equipment correctly, avoiding efficiency issues or damage caused by human error. As a leading Chinese boiler manufacturer, EPCB Boiler not only provides technical support but also helps customers maximize productivity, protect their investments, and ensure the continuous, efficient operation of their boilers through top-notch after-sales service.

Main Goals of After-Sales Service

Thermal oil boilers, as critical industrial heating equipment, have a direct impact on a company’s production efficiency and cost control. Providing quality after-sales service is essential to ensuring the safe and stable operation of thermal oil boilers. Effective after-sales service not only helps customers solve equipment problems but also brings long-term benefits from various angles.

1.Ensuring Normal Equipment Operation

The stable operation of thermal oil boilers is crucial to the continuity of production. The primary goal of after-sales service is to ensure the boiler system operates efficiently through regular maintenance and inspections. By regularly checking the operating status of the equipment and identifying and addressing potential issues early, companies can avoid downtime losses due to equipment failure. This not only ensures smooth production but also reduces additional repair costs that could arise from failures. Additionally, professional technical teams can provide targeted operational advice based on the equipment’s performance, optimizing boiler efficiency.

2.Extending Equipment Lifespan

The lifespan of a thermal oil boiler depends not only on the quality of the equipment itself but also on regular maintenance and upkeep. Through professional maintenance services, the after-sales team can regularly clean, adjust, and lubricate the equipment to prevent wear and tear and aging of parts from prolonged operation. Moreover, after-sales service can provide customized maintenance plans tailored to the specific working environment of the equipment, thereby extending the boiler’s lifespan. This planned maintenance approach reduces the frequency of equipment replacements and saves clients substantial capital investments.

3.Enhancing Customer Satisfaction

Customer satisfaction is a key measure of after-sales service quality. Effective after-sales service should include a quick response to customer needs and the provision of high-quality service. During the use of thermal oil boilers, customers may encounter various issues, such as abnormal equipment operation or improper parameter settings. The after-sales service team must have an efficient response mechanism to arrive on-site or provide remote technical support in the shortest time possible to resolve issues. Additionally, by offering detailed operational training and technical guidance, after-sales service can help clients master the correct use of the equipment, further enhancing customer satisfaction.

4.Reducing Equipment Failure Rate

The failure rate of equipment directly impacts a company’s production efficiency and operational costs. One of the key goals of after-sales service is to reduce the occurrence of equipment failures through preventive maintenance. Preventive maintenance includes regularly inspecting various components of the boiler system, replacing worn parts, and monitoring operational parameters. This proactive maintenance strategy allows problems to be detected before failures occur, enabling repairs to be made in advance and avoiding production interruptions due to sudden breakdowns. Additionally, by regularly diagnosing and upgrading equipment, the after-sales service team can continuously optimize the boiler's performance, further reducing the likelihood of failures.

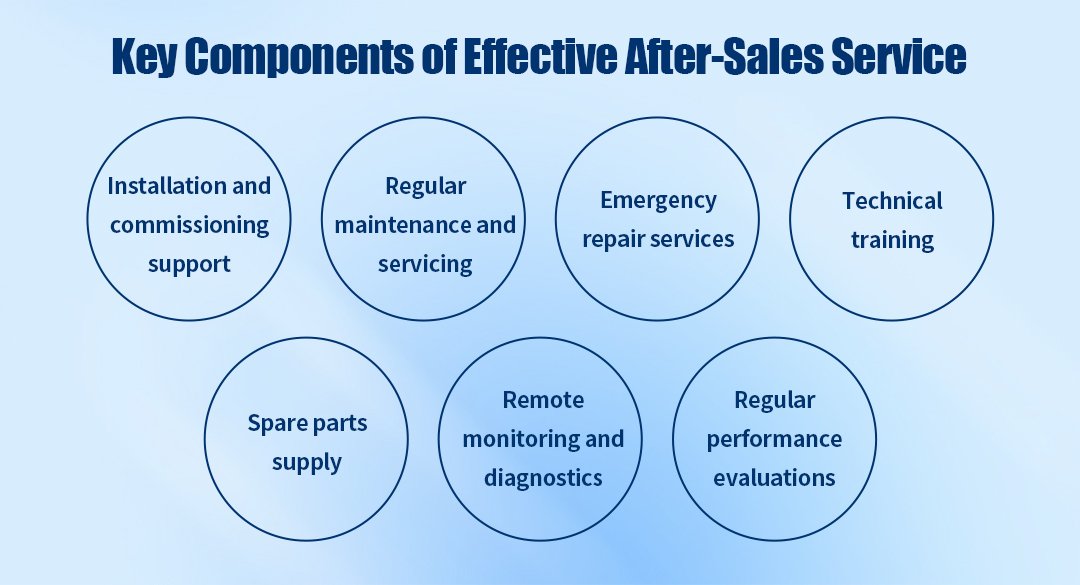

Key Components of Effective After-Sales Service

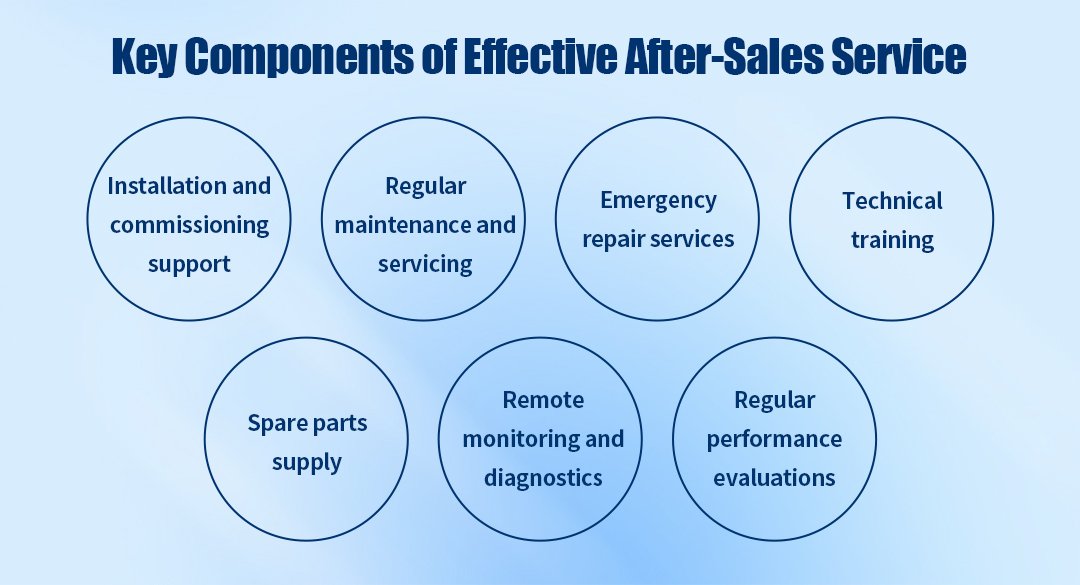

High-quality after-sales service is crucial during the use of thermal oil boilers. It not only ensures stable equipment operation but also provides comprehensive support and assurance to customers. Effective after-sales service is reflected in various aspects, including installation and commissioning support, regular maintenance, emergency repair services, technical training, spare parts supply, remote monitoring and diagnostics, and periodic performance evaluations.

1. Installation and Commissioning Support

Professional Installation Services

The installation of a thermal oil boiler is the first step in putting the equipment into operation, and it must be carried out by an experienced professional team. After-sales service should include the entire process management, from transportation of the equipment to on-site installation, ensuring the boiler is installed in compliance with all safety and operational regulations. Professional installation services can prevent future issues caused by improper installation, ensuring the stability and safety of the equipment.

Boiler System Commissioning

After installation, the after-sales team must carry out detailed system commissioning. This includes checking the tightness of all connections, testing the flow of the thermal oil, and ensuring that all boiler parameters meet design requirements. The purpose of commissioning is to confirm the normal operation of the equipment and ensure it meets expected performance standards. The commissioned equipment should be able to operate efficiently and safely under actual working conditions, avoiding performance deviations after startup.

2. Regular Maintenance and Upkeep

Developing Detailed Maintenance Plans

Regular maintenance and upkeep are essential for extending the life of a thermal oil boiler. After-sales service should develop a detailed maintenance plan based on the equipment’s working environment and intensity. This plan should include regular inspections, cleaning of the thermal oil system, and monitoring of operational parameters. These measures ensure that the equipment remains in optimal working condition.

Replacing Wearable Parts

The long-term stable operation of equipment relies on the timely replacement of wearable parts. After-sales service should regularly inspect the boiler’s wearable components, such as seals, filters, pumps, and valves, and replace them based on their wear levels. Preventative replacement effectively reduces the failure rate of the equipment, avoiding production disruptions caused by component failures.

3. Emergency Repair Services

24/7 Emergency Repair Hotline

Sudden equipment failures may occur during production, and quick response is crucial to minimizing losses. Effective after-sales service should provide a 24/7 emergency repair hotline, ensuring customers can access support at any time. The quick response mechanism of the repair hotline helps customers resolve issues promptly and resume production.

On-Site Repair Services

For problems that cannot be resolved through remote guidance, the after-sales service team should quickly dispatch technicians for on-site repairs. Fast on-site repair services not only reduce downtime caused by equipment failures but also allow for more accurate problem resolution through face-to-face communication with the customer.

4. Technical Training

Professional Technical Training

To ensure customers can correctly operate thermal oil boilers, after-sales service should provide professional technical training for the customer’s operators. Training content should include the operation procedures, daily maintenance methods, and troubleshooting techniques for common issues. Through training, customer operators can proficiently operate the equipment, reducing problems caused by improper operation.

Operation Manuals and Safety Guidelines

In addition to on-site training, after-sales service should provide detailed operation manuals and safety guidelines. These documents help operators follow the correct procedures during actual operation, ensuring the safe use of the equipment. Additionally, operation manuals and safety guidelines assist new employees in quickly getting up to speed, reducing training costs.

5. Spare Parts Supply

Timely Supply of Common Spare Parts

The supply speed of spare parts directly impacts the efficiency of equipment repairs. Effective after-sales service should establish a comprehensive spare parts supply chain to ensure that common spare parts are readily available. By providing spare parts promptly, extended downtimes due to a lack of parts can be avoided, ensuring continuous production.

Provision of High-Quality Original Parts

After-sales service should also ensure that all supplied parts are high-quality original parts. Original parts not only perfectly match the equipment’s performance but also extend its lifespan, preventing secondary failures caused by inferior parts.

6. Remote Monitoring and Diagnostics

Remote Monitoring Services

With the development of technology, remote monitoring has become an important part of after-sales service. By providing remote monitoring services, the after-sales team can monitor the operational status of the thermal oil boiler in real time and detect any abnormalities early. Remote monitoring not only improves the efficiency of equipment management but also provides data support for preventive maintenance.

Remote Diagnostics

In addition to monitoring, after-sales service can also utilize remote diagnostics to identify potential problems in advance. By analyzing equipment operation data, technicians can preemptively detect issues and provide customers with advice for early resolution. Remote diagnostics reduce the occurrence of sudden failures and enhance equipment reliability.

7. Periodic Performance Evaluation

Regular Performance Evaluation

To ensure that thermal oil boilers remain in optimal condition, after-sales service should conduct regular performance evaluations. These evaluations should cover operational efficiency, energy consumption levels, and emission rates. By assessing these factors, customers can gain insight into the actual operational status of the equipment and make timely adjustments to operational parameters or carry out necessary maintenance.

Providing Improvement Suggestions

Based on the performance evaluations, the after-sales service team should offer suggestions for optimizing equipment use. These suggestions may include adjusting operational methods, upgrading certain equipment, or improving the maintenance plan. Through these improvements, customers can further enhance equipment efficiency and reduce operating costs.

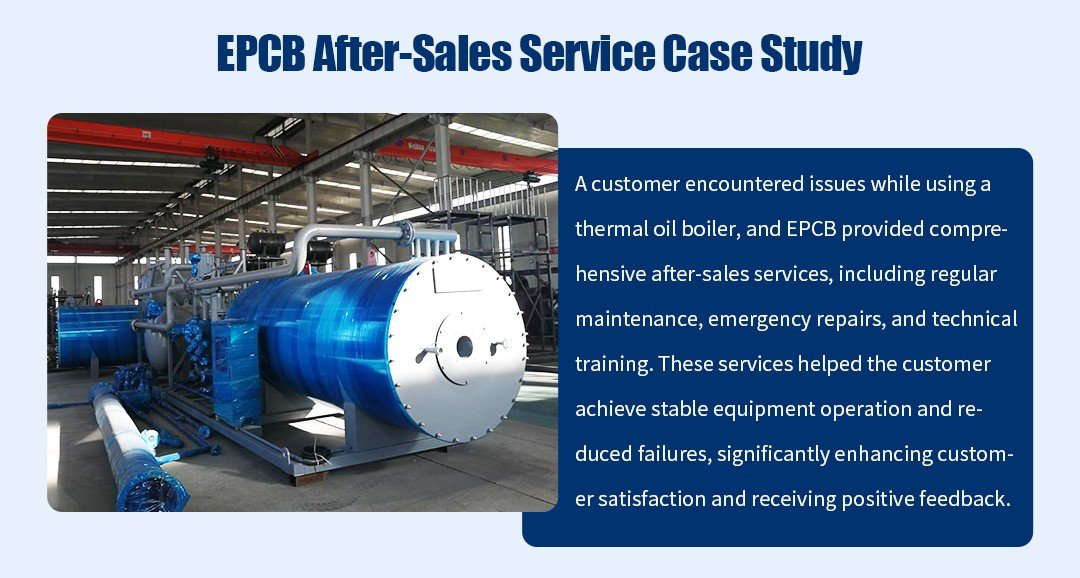

EPCB After-Sales Service Case Study

EPCB Boiler is a professional boiler manufacturer dedicated to providing high-efficiency, safe, and environmentally friendly boiler products to customers worldwide. In addition to producing high-quality boiler equipment, EPCB has established a comprehensive after-sales service system to ensure the continuous and stable operation of equipment after installation. EPCB’s after-sales services cover a wide range of areas, including installation and commissioning, regular maintenance, emergency repairs, and technical training, offering full support to its customers. Through this comprehensive service, EPCB not only helps customers resolve various issues during the use of the equipment but also significantly enhances customer satisfaction and extends the lifespan of the equipment.

Project Background

A large chemical company purchased and installed an EPCB thermal oil boiler to supply heat for its production line. During the initial operation phase, the customer noticed occasional temperature fluctuations in the equipment, which led to reduced production efficiency. In addition, due to the operators’ lack of familiarity with the equipment, improper operation caused minor malfunctions, affecting the normal production schedule. Facing these challenges, the customer contacted EPCB, hoping that professional after-sales service could resolve the equipment's operational instability and address the operators' technical issues.

Provided Solution

In response to the issues the customer encountered while using the thermal oil boiler, EPCB quickly organized an after-sales service team to provide a solution.

Emergency Repairs

First, the EPCB after-sales team responded promptly to the customer’s report and dispatched technicians to the site. Through on-site troubleshooting and emergency repairs, the problem was effectively resolved in a short period, allowing production to resume quickly. EPCB also set up a 24/7 emergency repair hotline for the customer to ensure that any future unexpected issues could be addressed promptly.

Regular Maintenance

EPCB developed a detailed regular maintenance plan for the customer. Each quarter, EPCB technicians conducted a comprehensive inspection of the boiler system, including quality testing of the thermal oil, checking the sealing of pipes and valves, and cleaning and adjusting the equipment. These maintenance measures ensured that the equipment operated efficiently and minimized issues caused by equipment aging or wear.

Techncal Training

To improve the skill level of the customer’s operators, EPCB provided a systematic training course for the technical staff. The training covered basic operational procedures, common fault diagnostics and handling, and safety operation guidelines. Through this training, the operators became more proficient in using and maintaining the equipment, reducing malfunctions caused by improper operation.

Results and Benefits

With the support of EPCB's after-sales service, the customer's thermal oil boiler system achieved stable operation. The temperature fluctuation issue was resolved, production efficiency significantly increased, and the equipment failure rate was greatly reduced. Through regular maintenance and technical training, the equipment's lifespan was extended, and the customer no longer needed to frequently shut down for repairs, saving substantial operational costs.

The customer expressed a high level of satisfaction with EPCB's after-sales service. They especially appreciated the EPCB team's quick response, professional skills, and comprehensive training services, which greatly enhanced their production efficiency and operational safety. The customer stated that EPCB’s after-sales service not only helped them solve practical problems but also increased their confidence in the equipment, and they plan to continue partnering with EPCB in the future.

Through this after-sales service case, EPCB demonstrated its strong ability to address the actual needs of customers, further solidifying its leading position in the boiler industry.

Best Practices for Enhancing After-Sales Service Quality: EPCB Boiler’s Excellence in Service

1. Establishing Customer Profiles

At EPCB, we understand that each boiler is unique, which is why creating a detailed profile for every customer is essential. These profiles not only record basic information like the boiler model and installation date but also track the equipment's operational status, maintenance history, and customer feedback. These comprehensive records enable EPCB's after-sales team to quickly understand the equipment's condition in future services, allowing for more precise and efficient support.

2. Regular Customer Follow-Up

To ensure that EPCB boilers always operate at their best, we maintain a regular follow-up schedule with our customers to check on the actual performance of the equipment. These follow-ups help us identify potential issues customers may face and allow us to continuously improve our service strategies based on their feedback. EPCB's follow-up service not only provides customers with attentive care but also significantly enhances their satisfaction with our brand.

3. Ongoing Technical Training

Technical expertise is key to ensuring the efficient operation of EPCB boilers. We regularly update our technical training content to ensure that customers' operators can stay up-to-date with the latest operational skills. Through regular training courses and technical updates, EPCB helps customers stay ahead in a competitive market, ensuring that their boilers perform optimally in real-world operations. This continuous technical support not only improves equipment efficiency but also boosts customer confidence.

4. Feedback Mechanism

At EPCB, we regard customer needs as a valuable resource for improving our service. We have established multiple channels for collecting customer feedback, including online surveys and phone interviews, to ensure that customer opinions reach our service team promptly. By conducting in-depth analysis of feedback, EPCB continuously optimizes its service processes, addressing common issues and improving overall service quality. It is this strong emphasis on customer feedback that allows EPCB to consistently exceed customer expectations, earning widespread trust and praise.

FAQ

1. What is the response time for after-sales service?

EPCB Boiler is committed to responding to customer service requests within 24 hours at the latest. If the customer is located within the coverage area of our service team, we will strive to dispatch technicians to the site on the same day. For emergencies, we also offer a 24/7 emergency repair hotline to ensure that your issue is addressed as quickly as possible.

2. What does after-sales service include?

EPCB’s after-sales service covers a wide range of areas, including equipment installation and commissioning, regular maintenance, emergency repairs, and technical training. We create customized maintenance plans for each customer, which include periodic inspections, cleaning, and replacement of key components. Additionally, we offer remote monitoring and regular performance evaluations to ensure that your equipment is always in optimal operating condition.

3. Do you offer a warranty?

EPCB offers a standard warranty for thermal oil boilers, typically lasting one year. During the warranty period, we will repair any equipment malfunctions caused by product quality issues free of charge. Customers can also choose to extend the warranty, and the specific terms can be customized based on the customer’s actual needs, ensuring comprehensive protection throughout the equipment's lifecycle.

4. How are emergencies handled?

In the event of an emergency during equipment operation, customers can immediately contact EPCB’s 24/7 emergency repair hotline. Our technical team will promptly reach out to you, providing quick solutions either through remote guidance or on-site repairs, minimizing downtime and ensuring continuous production.

5. Do you offer customized services?

EPCB understands that each customer’s needs are unique, which is why we offer customized after-sales service solutions. Whether it’s developing a maintenance plan or arranging technical training, we can tailor our services to meet the specific requirements of each customer. We are committed to providing the most suitable solutions to help you succeed in your business.

Conclusion

Effective after-sales service is crucial to the longevity and stable operation of thermal oil boilers. Through regular maintenance, professional installation and commissioning, emergency repair services, and technical training, customers can ensure that their equipment remains in optimal condition, maximizing their return on investment. In addition, services such as spare parts supply, remote monitoring, and regular performance evaluations further reduce the likelihood of equipment failures, enhancing customer satisfaction.

Looking ahead, after-sales services will continue to improve with advancements in technology. We anticipate that, supported by digitalization and automation, remote monitoring and diagnostics will become more precise and efficient, with faster and higher-quality service responses. Moreover, customer training and feedback mechanisms will become more refined, helping customers stay ahead in the operation and maintenance of their equipment.

Therefore, choosing a reliable after-sales service is not only a guarantee for the equipment but also a commitment to the long-term stable development of the business. By partnering with high-quality suppliers like EPCB, customers can ensure that their thermal oil boilers operate safely and efficiently throughout their entire lifecycle, leading to greater productivity and profitability.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler