In the rapidly developing pharmaceutical industry, efficiency and precision are paramount, and thermal oil boilers are a key technology that can significantly enhance both qualities. Successfully integrating thermal oil boilers into existing pharmaceutical production lines can greatly improve operational performance. As a leading boiler manufacturer in China, EPCB Boiler is well-versed in the industry's needs, committed to providing customers with efficient and precise heating solutions.

This article will provide a detailed overview of the basic steps and considerations for integrating thermal oil boilers with pharmaceutical production equipment and demonstrate how EPCB Boiler helps pharmaceutical companies achieve leaps in production efficiency through superior product design and manufacturing, allowing them to stand out in a highly competitive market.

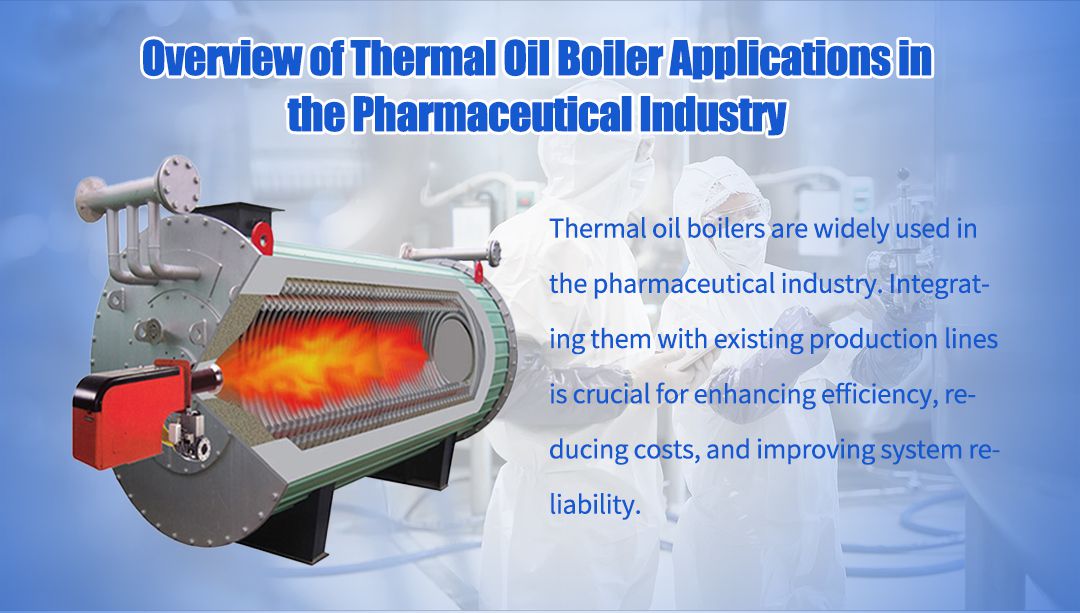

Overview of Thermal Oil Boilers in the Pharmaceutical Industry

Thermal oil boilers have been widely adopted in the pharmaceutical industry due to their excellent temperature control capabilities. Many processes in pharmaceutical production have extremely strict temperature requirements, where even minor fluctuations in temperature can impact the quality and effectiveness of the final product. Integrating thermal oil boilers can improve production efficiency, reduce energy costs, and ensure consistent product quality.

Seamless integration of thermal oil boilers with existing production lines is essential for ensuring the continuous and efficient operation of pharmaceutical enterprises. Proper integration avoids conflicts between new equipment and existing processes and minimizes production disruptions, maximizing the benefits of thermal oil heating. EPCB has extensive experience in helping clients achieve system integration, designing the optimal solution based on the specific needs of each enterprise to ensure the perfect collaboration between new and existing systems.

Integrating thermal oil boilers into existing production lines brings significant advantages. First, it improves temperature control, making pharmaceutical processes more precise and enhancing product quality. Second, it increases overall production efficiency by reducing downtime and waste caused by temperature fluctuations or equipment misalignment. Finally, the integrated system can effectively lower energy costs and boost economic efficiency.

Evaluating the Needs of Existing Pharmaceutical Production Lines

1.Process Analysis of the Existing Production Line

Heat Energy Demand Analysis:

Firstly, a thorough analysis of all process steps within the pharmaceutical production line is necessary to determine their heat energy requirements. Special attention should be given to processes that involve heating, drying, evaporation, or reactions, as these often have very stringent temperature control requirements. By assessing the temperature ranges and heat stability needed at each production stage, a reference for selecting the thermal oil boiler can be provided. The thermal oil boiler, with its ability to provide constant high-temperature heat energy, is particularly suitable for processes requiring continuous, uniform heating.

Identifying the Stages for Thermal Oil Boiler Integration:

Through the analysis of production processes, it is essential to determine which stages are most suitable for the thermal oil boiler's heat energy supply. For example, drying towers, heating reactors, and distillation units are key targets for the integration of thermal oil boilers. These devices have high requirements for precise temperature control, and the thermal oil boiler can provide accurate heat delivery.

2. Space and Layout of the Production Line

Space Layout Evaluation:

In the integration process, the installation location of the boiler is crucial. The available space in the production facility should be evaluated, taking into account the size of the equipment and the ease of maintenance. The boiler needs to be placed in an area that is easy to maintain and operate, while not disrupting the existing production processes or causing congestion. Ventilation requirements should also be considered to ensure air circulation in the boiler area and avoid overheating.

Piping Planning and Connections:

The design of the piping is also critical. An efficient thermal oil piping system must be designed to minimize heat loss while maintaining stable heat energy supply across various stages of the production line. The piping should avoid unnecessary bends and overly long routes to ensure efficient heat transfer. Insulation measures for the pipes are also important to prevent heat loss during transmission.

3. Equipment Compatibility

Checking the Compatibility of Equipment with the Boiler:

Integrating a thermal oil boiler requires not only evaluating the performance of the boiler itself but also ensuring that the existing equipment can seamlessly connect with the new boiler. First, check whether the current equipment, such as heat exchangers, reactors, and evaporators, can directly connect to the thermal oil system. If the operating temperature or pressure of the existing equipment does not match, it may need appropriate modifications or upgrades to ensure compatibility with the new system.

Demand for Equipment Modification or Replacement:

If some equipment cannot reach optimal performance after being connected to the thermal oil boiler, corresponding components may need to be replaced, or the system may need to be upgraded. For example, additional insulation layers may need to be added to the heat exchangers, or some old equipment may need to be upgraded to adapt to the high-temperature environment provided by the thermal oil boiler.

Steps for Integrating a Thermal Oil Boiler with a Production Line

1. Design an Integration Plan

Boiler Selection and Piping Layout:

Based on the heat energy requirements of the production line, select the appropriate model of the thermal oil boiler to ensure its output capacity can meet the necessary heat demand for production. At the same time, the piping layout should consider the efficient transfer of heat energy and the minimization of heat loss. The design plan should include the location of the boiler, the routing of the piping, and the determination of connection points, ensuring smooth heat flow between all equipment.

Compliance with Industry Standards and Safety Regulations:

All design plans must strictly adhere to relevant industry standards and safety regulations. This includes compliance with local regulations and international standards concerning boiler pressure levels, temperature ranges, and piping material selection. Safety systems such as safety valves, automatic shutdown devices, and overheating protection should also be prioritized in the design.

2. Installation and Commissioning

Equipment Installation:

When installing the thermal oil boiler and its associated equipment, follow the layout provided in the design plan. The boiler should be installed securely, ensuring that its foundation is well-matched to the surrounding environment. The connections between the piping and the equipment must ensure a proper seal to avoid oil leaks or heat loss.

Connection to the Production Line:

The thermal oil boiler's heat output pipes should seamlessly connect to the heat demand points of the production line. According to the production process, the boiler’s heat supply points should interface with key equipment such as reactors, distillers, and drying equipment, ensuring even and stable heat distribution throughout the production process.

System Commissioning:

After installation, the system needs to undergo comprehensive commissioning. All connections should be inspected for sealing and safety to ensure that the piping, equipment, and the boiler itself operate correctly under high temperature and pressure. During commissioning, verify that all parameters (such as temperature, pressure, and flow rate) meet the design requirements and promptly address any potential hazards.

3. Control System Integration

Automation Control System Integration:

The thermal oil boiler’s control system must be integrated with the existing production line’s automation control system. Through this step, the production line can achieve real-time monitoring and regulation of the boiler’s temperature, pressure, and other parameters. System integration should also ensure that the boiler can communicate and share data effectively with other control equipment in the production line, allowing for automated operation.

Monitoring and Regulation of Key Parameters:

Through the integration of an automation system, operators can monitor the operating status of the thermal oil boiler in real-time, triggering alarms and shutdowns in case of any abnormalities. Precise control of parameters such as temperature and pressure is crucial for the safety of the thermal oil boiler and the stability of the production line.

4. Training and Support

Operator Training:

After integrating the thermal oil boiler, providing comprehensive training for operators is critical. The training should cover basic boiler operation methods, use of the automation system, troubleshooting, and key points of daily maintenance. Through systematic training, operators will be able to ensure the safe and stable operation of the equipment in daily work.

Technical Support and Maintenance:

In addition to training, long-term technical support should be provided to ensure any issues that arise during production can be promptly addressed. A regular maintenance plan should also be developed, including inspections, cleaning, and replacement of key components for the boiler and piping, ensuring the system's long-term efficient operation.

Advantages of Integrating a Thermal Oil Boiler

1. Improve Production Efficiency

Precise Heat Control Enhances Efficiency and Stability:

Thermal oil boilers can provide precise and consistent temperature control, ensuring that the required heat is supplied accurately at each stage of the process. This stability not only reduces fluctuations during production but also ensures consistent product quality, thereby improving overall process efficiency.

Shorten Production Cycles and Increase Capacity:

Because thermal oil boilers can respond quickly to heat demand, production lines can reach the required working temperature faster, reducing preheating and processing times. This directly shortens production cycles, increases the output within a given time, and thereby boosts production capacity.

2. Reduce Operating Costs

Improve Heat Utilization Efficiency and Reduce Energy Consumption:

Thermal oil boilers minimize heat loss through highly efficient heat transfer systems, optimizing heat utilization. Compared to traditional heating methods, their energy consumption is significantly reduced. This energy-saving effect can noticeably lower energy costs during long-term production.

Simple Maintenance, Lower Maintenance Costs:

The design and integrated system of thermal oil boilers are relatively simple, resulting in lower daily maintenance requirements. This not only reduces maintenance costs but also decreases the frequency of downtime for maintenance, ensuring continuous production.

3. Enhance System Reliability

Increased System Stability and Reduced Failure Rates:

Thermal oil boilers are highly reliable, and their stable operating performance reduces the likelihood of equipment failure. Compared to traditional boilers, the lower pressure in thermal oil systems reduces the risk of equipment aging and damage, further improving system reliability.

Reduced Downtime and Increased Production Line Reliability:

Since thermal oil boilers have a lower failure rate, the downtime of the entire production line is correspondingly reduced, ensuring higher equipment availability. This reliability not only reduces the losses caused by unexpected stoppages but also enhances the continuity and efficiency of production.

4. Environmental Benefits

Reduced Emissions, Supporting Environmental Protection:

Compared to traditional boilers, thermal oil boilers produce fewer emissions, effectively reducing the release of harmful gases. This sets a higher standard for environmental protection in pharmaceutical companies while helping to reduce their negative impact on the environment.

Compliance with Strict Environmental Regulations:

Many countries are imposing stricter environmental regulations on the pharmaceutical industry. Integrating thermal oil boilers can help companies meet these regulatory requirements. The low-emission design not only complies with current environmental regulations but also prepares companies for stricter standards in the future.

EPCB Case Study: Successfully Integrating a Thermal Oil Boiler into Pharmaceutical Production

EPCB Boiler is renowned for its expertise in the design, integration, and maintenance of thermal oil boiler systems, particularly in the pharmaceutical industry, where it has successfully helped numerous companies optimize their production processes. With years of accumulated technical experience and a deep understanding of industry needs, EPCB provides clients with customized thermal oil boiler integration solutions.

1. Pharmaceutical Plant’s Needs and Challenges

In this case, a pharmaceutical plant faced two major issues: First, inconsistent heating led to temperature fluctuations during production, affecting the stability of product quality. Second, due to the inefficiency of the existing heating system, the plant’s energy costs continued to rise, severely impacting the economic viability of production. To address these challenges, the pharmaceutical plant needed a solution that could provide precise temperature control while significantly improving energy efficiency.

2. EPCB’s Integration Approach

Based on the client’s specific needs, EPCB Boiler developed a comprehensive integration plan to ensure that the thermal oil boiler could seamlessly connect with the existing production line. The plan included several key steps:

Boiler Selection: Based on the pharmaceutical plant’s heat energy requirements, EPCB selected an efficient thermal oil boiler, ensuring it could provide stable and precise heat output to meet the temperature requirements of various production stages.

Piping Optimization: EPCB conducted a detailed analysis of the entire production line’s physical layout and heat energy needs, designing an optimal piping layout to minimize heat loss while ensuring efficient heat transfer to each critical piece of equipment.

Control System Integration: EPCB integrated the thermal oil boiler’s control system with the pharmaceutical plant’s existing automation system, enabling real-time monitoring and adjustment of the boiler’s temperature, pressure, and heat output. This smart integration allowed the plant to precisely control the temperature at each stage of production, ensuring consistent product quality.

This customized integration plan not only minimized disruptions to the existing production process but also ensured the system’s efficient operation.

3. Post-Implementation Results

After the successful integration of the thermal oil boiler, the pharmaceutical plant achieved several improvements:

Increased Production Efficiency: Precise temperature control and stable heat supply significantly reduced fluctuations during the production process. The production cycle was shortened, and the overall output of the plant increased substantially.

Reduced Operating Costs: The high energy efficiency design of the thermal oil boiler helped the plant significantly reduce energy consumption, saving a substantial amount on fuel costs. In addition, the reduced maintenance requirements further lowered daily operating costs.

The pharmaceutical plant expressed high appreciation for the solution provided by EPCB. They particularly recognized EPCB’s professionalism and technical expertise throughout the integration process. From solution design to implementation, the support from the EPCB team ensured the smooth completion of the project and the achievement of the expected results.

Key Considerations During the Integration Process

1. Project Management

Develop a Detailed Project Plan and Timeline:

The first step to a successful integration is creating a comprehensive project plan that covers each stage from design and installation to commissioning. The plan should clearly outline the timeline for each phase, the required resources, and the responsible personnel, ensuring a clear and visualized workflow.

Monitor the Integration Process to Ensure Timely Completion:

The project management team should continuously monitor progress to ensure each step is completed on time. If any delays or issues arise, project managers must take corrective actions immediately to keep the project on track. Regular project status updates and communication are also critical to ensure coordination and information sharing among team members.

2. Safety Considerations

Ensure Compliance with Safety Standards:

During the integration of the thermal oil boiler, it is essential to strictly adhere to all relevant industry safety standards and regulations. This includes not only the safety requirements for equipment installation but also personnel safety management during production line operation. A risk assessment should be conducted early in the project, and corresponding countermeasures should be established.

Take Preventive Measures to Avoid Accidents:

In practical operations, especially when dealing with high-temperature and high-pressure equipment, preventive measures are key to avoiding accidents. The team should wear appropriate protective gear, ensure good ventilation in the work area, and use tools and equipment that meet safety standards. Regular safety inspections should also be conducted to ensure a safe environment across the plant.

3. Equipment Maintenance

Develop a Maintenance Plan for Equipment:

After successful integration, the long-term performance and stability of the equipment depend on regular maintenance. A detailed maintenance plan should be developed, including the inspection frequency, servicing requirements, and repair processes for each component. This will ensure the system’s stable operation over the long term and prevent production interruptions due to equipment failure.

Conduct Regular Inspections and Servicing to Ensure Long-Term Stability:

The maintenance plan should include daily inspections and periodic servicing, particularly for the boiler and piping, to ensure no leaks, stable pressure, and accurate temperature control. Additionally, the control system’s parameters should be continuously monitored and adjusted to ensure it can meet production needs.

4. Data Management

Data Management and Monitoring:

Once the thermal oil boiler is integrated, data management becomes an essential part of the control system’s effective operation. Through data collection and real-time monitoring, companies can track the system’s operational status and make necessary adjustments. The data management system should be able to record key parameters such as the boiler’s temperature, pressure, and energy consumption, and generate reports to help optimize the production process.

Ensure Data Accuracy and Security:

To avoid data errors or loss, the data management system must be highly reliable, with proper data backup and security measures. Particularly in highly automated pharmaceutical production environments, any inaccuracy or failure to update data promptly can negatively impact the production process. Implementing robust data encryption and backup mechanisms can ensure system stability and data security.

FAQ

Does integrating a thermal oil boiler require production downtime?

Integrating a thermal oil boiler may require temporary production downtime, but careful project planning and reasonable scheduling can minimize the impact on production. In some cases, partial downtime or integration during off-peak periods may be sufficient to reduce production disruption.

How long does the integration process take?

The integration time for a thermal oil boiler depends on the complexity of the production line and specific requirements. In general, the project may last from several weeks to a few months. A detailed assessment during the project planning phase will help determine a more accurate timeframe.

Will operating costs increase after integration?

While there may be some initial investment costs, the high energy efficiency of thermal oil boilers typically reduces long-term operating costs. By improving thermal efficiency and reducing energy consumption, companies can recoup their investment in a relatively short period.

Is it necessary to replace existing equipment?

Whether existing equipment needs to be replaced or upgraded depends on the compatibility of the current system. EPCB will conduct a detailed evaluation of the existing equipment and recommend upgrades or modifications as necessary to ensure seamless integration with the thermal oil boiler.

How to choose the right technical partner?

When selecting a technical partner, prioritize their experience and expertise in thermal oil boiler integration. Review successful case studies, client testimonials, and the technical support services they offer to ensure the project is executed smoothly.

Conclusion

In summary, integrating a thermal oil boiler with your pharmaceutical production line is undoubtedly a wise strategic decision, as the benefits are significant. From improving production efficiency and reducing operating costs to enhancing system reliability, the advantages of integration will be clearly reflected in your production processes.

Looking ahead, the ongoing development of thermal oil boiler technology will continue to drive innovation and progress in the pharmaceutical industry. Companies that take proactive steps to integrate advanced heating systems will gain a clear advantage in terms of capacity and competitiveness.

With years of industry experience and technical expertise, EPCB Boiler is committed to providing reliable and efficient heating solutions to pharmaceutical companies worldwide. If you are considering integrating a thermal oil boiler into your production line, the EPCB team is ready to offer expert advice and customized integration plans to support you through every step of the process, from planning to implementation. Now is the perfect time to take action—partner with EPCB and embark on a future of efficient and energy-saving production!

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler