1. Importance of Thermal Oil Boilers in the Pharmaceutical Industry

A thermal oil boiler is a heat energy device that uses thermal oil as the heat transfer medium. Its main function is to heat thermal oil by burning various fuels (such as natural gas, diesel, biomass, etc.), which then transfers heat to the end-use equipment. Thermal oil boilers are characterized by high temperature and low pressure, safety, efficiency, and precise temperature control, making them widely used in industrial fields that require continuous high temperatures and stable heat supply.

In the pharmaceutical industry, thermal oil boilers play a crucial role by ensuring that processes such as distillation, drying, and reactor heating operate in a precise and stable high-temperature environment, thereby ensuring product quality. Their high efficiency and energy-saving features significantly reduce the energy consumption costs of pharmaceutical enterprises, while the lower working pressure design enhances operational safety, meeting the industry's stringent safety standards. Moreover, the advanced temperature control system enables precise temperature regulation, further ensuring the stability of the pharmaceutical process.

As a leading boiler manufacturer, EPCB leverages its innovative technology and extensive industry experience to provide high-quality thermal energy solutions for the pharmaceutical industry. EPCB's thermal oil boilers use advanced heat transfer technology to ensure high efficiency and precise temperature control, meeting the stringent requirements for high-temperature stability in pharmaceutical production. Additionally, EPCB boilers excel in energy saving and environmental protection, supporting the sustainable development of pharmaceutical enterprises by reducing energy consumption and emissions.

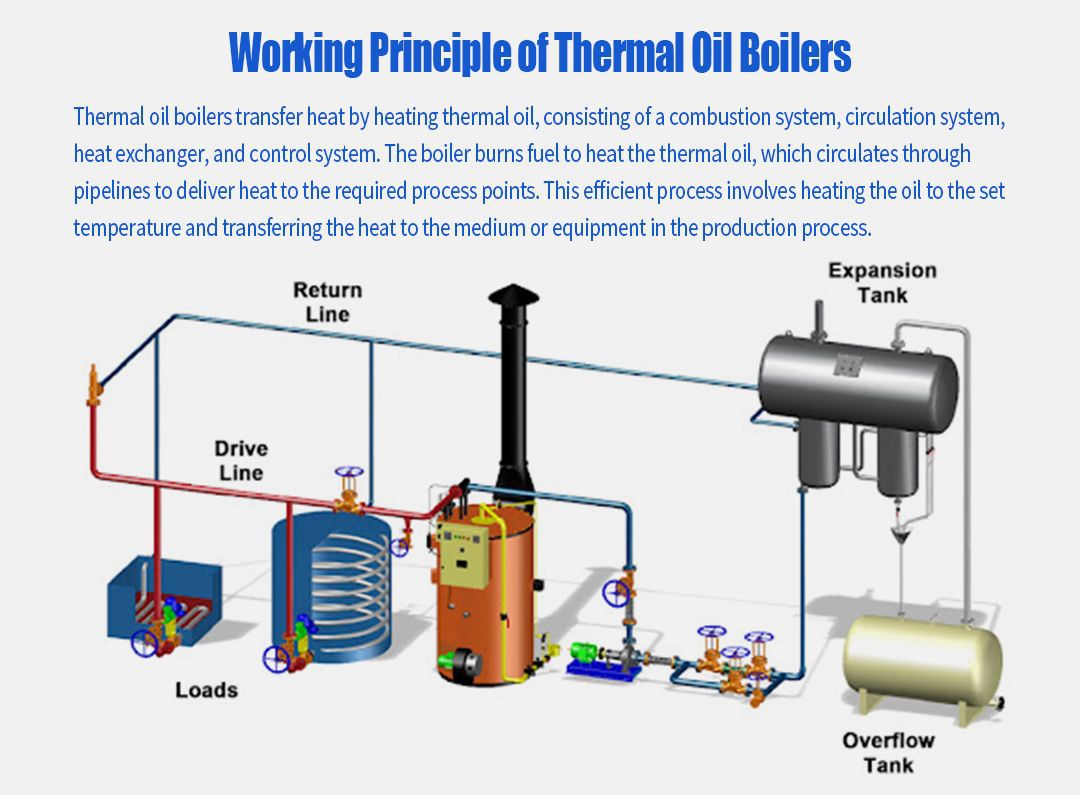

2. Working Principle of Thermal Oil Boilers

2.1 Basic Definition of Thermal Oil Boilers

A thermal oil boiler is a heating device that uses thermal oil as the medium to transfer heat by burning fuel. Unlike traditional steam boilers, thermal oil boilers can achieve high-temperature heating at lower pressures, offering advantages such as high efficiency, safety, and stability. They are widely used in industries such as petroleum, chemical, pharmaceutical, and food processing.

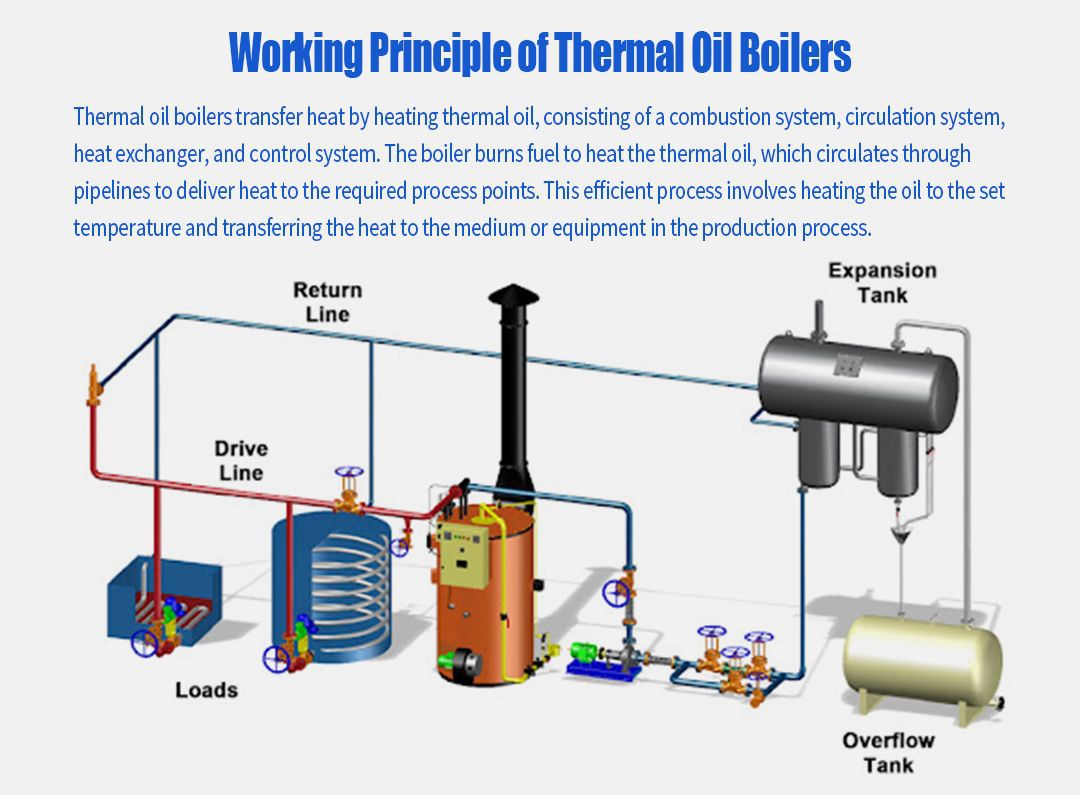

2.2 Main Components of Thermal Oil Boilers

The main components of a thermal oil boiler include the burner, thermal oil furnace body, circulation pump, expansion tank, temperature control system, and safety devices. The burner mixes fuel (such as natural gas, diesel, or coal) with air and ignites it, producing high-temperature flames that heat the thermal oil. The furnace body contains coils or serpentine pipes where the thermal oil flows and absorbs heat. The circulation pump drives the thermal oil through the system, ensuring heat is transferred to various heating points.

2.3 How Do Thermal Oil Boilers Transfer Heat?

Thermal oil boilers transfer heat by burning fuel in the burner to produce high-temperature flames and flue gases, which flow through the furnace body and heat the thermal oil in the pipes. The thermal oil absorbs the heat and is pumped to the equipment or system that needs heating. Through heat exchangers or direct contact, the thermal oil transfers heat to the process medium or product, raising its temperature. The cooled thermal oil returns to the boiler to be reheated, continuing the cycle and achieving efficient heat transfer. This method allows thermal oil boilers to provide high-temperature heating at low pressure, with high energy utilization, stable operation, and safety, making them suitable for various industrial heating needs.

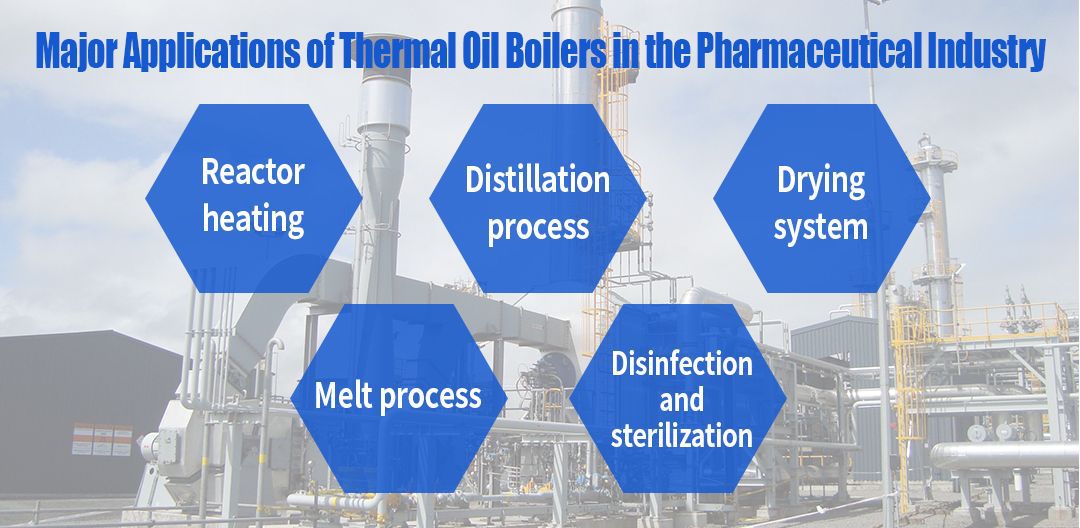

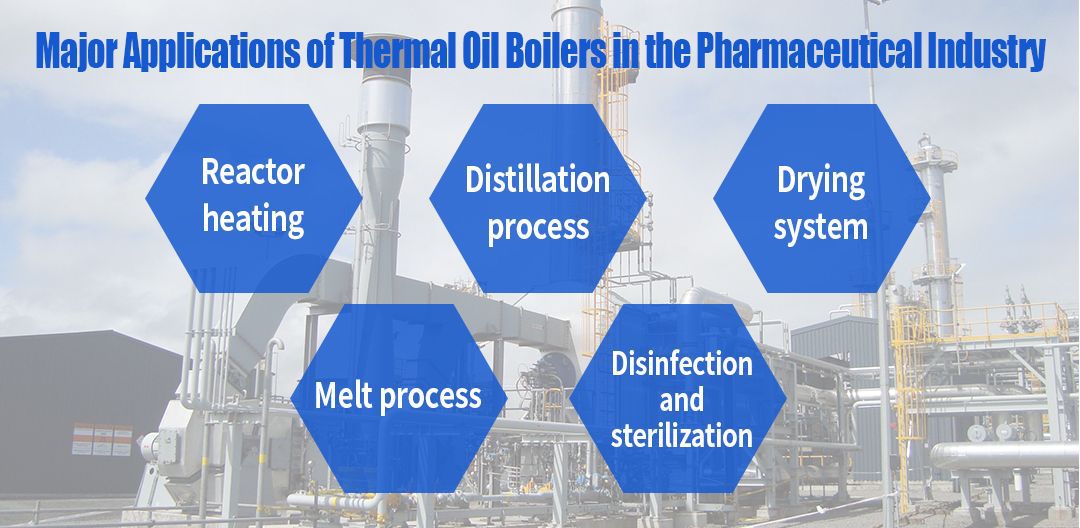

3. Applications of Thermal Oil Boilers in the Pharmaceutical Industry

Thermal oil boilers, with their excellent heat transfer performance and versatile application scenarios, have become the preferred choice for many manufacturing enterprises. Their main application areas include reactor heating, distillation processes, drying systems, melting processes, and sterilization and disinfection. This fully demonstrates their wide-ranging importance in the manufacturing industry. The following sections will detail the specific applications and advantages of thermal oil boilers in these key processes.

3.1. Reactor Heating

Thermal oil boilers are widely used for heating reactors in the pharmaceutical industry. Chemical reactions within reactors require strict temperature control to ensure reaction efficiency and product purity. Thermal oil boilers provide a stable, uniform high-temperature heat source, allowing precise control of the reactor temperature. For example, in the production of certain antibiotics, the reactor temperature needs to be maintained within a specific range. The use of thermal oil boilers ensures the smooth operation of the entire reaction process, improving product quality and yield.

3.2. Distillation Process

In the pharmaceutical industry, distillation is a crucial step for extracting purified chemical substances. Thermal oil boilers provide an efficient and stable heat source for distillation equipment, making temperature control more precise. The application of thermal oil boilers significantly improves the efficiency of the distillation process, allowing the required temperature to be quickly reached and reducing energy consumption. For example, in the extraction of essential oils, thermal oil boilers ensure stable heating of the distillation equipment, resulting in higher purity and efficiency of the extracted essential oils.

3.3. Drying Systems

Thermal oil boilers also play an important role in drying systems within the pharmaceutical industry. During production, pharmaceuticals and chemical reagents need to undergo drying processes to remove moisture and solvents. The high-temperature heat source provided by thermal oil boilers makes the drying process more efficient and uniform. For instance, in the drying of certain powdered drugs, the application of thermal oil boilers can significantly shorten drying times, improve production efficiency, and ensure consistency in the quality of the dried products.

3.4. Melting Processes

Thermal oil boilers are crucial in certain melting processes within the pharmaceutical industry. During drug production, certain solid raw materials need to be melted into liquid form for subsequent processing and handling. Thermal oil boilers provide a stable high-temperature environment, ensuring the smooth progress of the melting process. For example, in the production of certain medicinal wax products, thermal oil boilers maintain a stable temperature in the melting vessel, enhancing the efficiency and stability of the melting process.

3.5. Sterilization and Disinfection

Thermal oil boilers also play a key role in the sterilization and disinfection processes in the pharmaceutical industry. During pharmaceutical production, strict sterilization and disinfection are necessary to ensure product safety and compliance. The high-temperature heat source provided by thermal oil boilers effectively kills microorganisms, ensuring thorough sterilization and disinfection. For instance, when disinfecting pharmaceutical production equipment, thermal oil boilers can provide continuous high-temperature steam, ensuring that all microorganisms on the equipment surfaces are thoroughly eliminated, thereby ensuring a safe and hygienic production process.

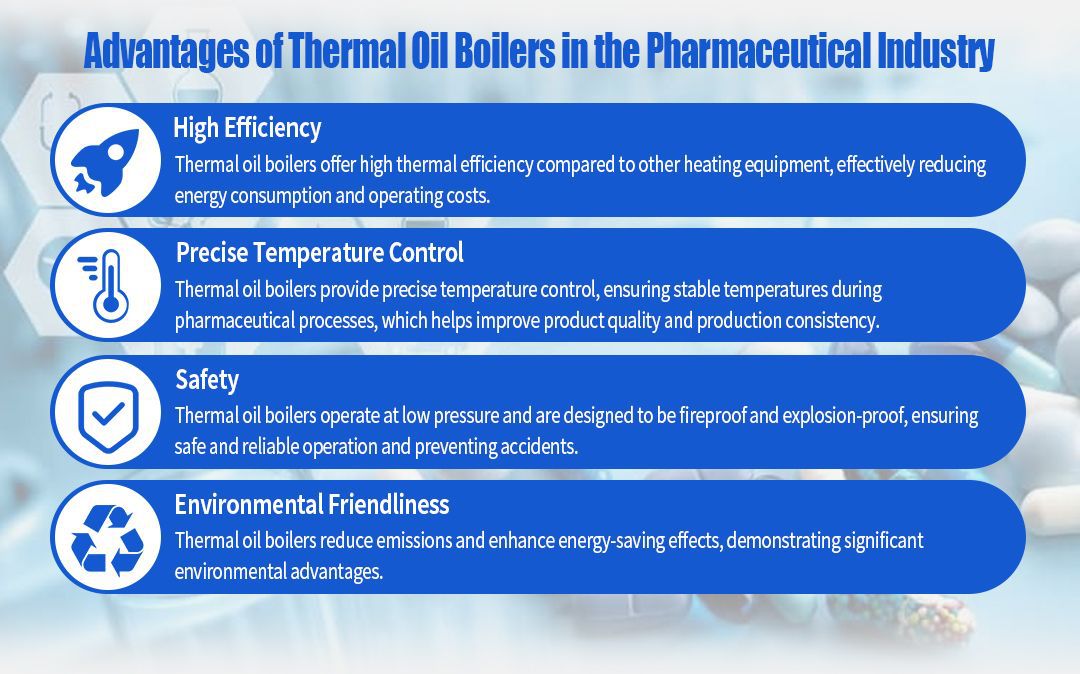

4. Advantages of Thermal Oil Boilers in the Pharmaceutical Industry

Compared to other boilers, thermal oil boilers are the ideal choice for pharmaceutical enterprises due to their outstanding high efficiency, precise temperature control, safety, and environmental friendliness. In the pharmaceutical industry, efficient, precise, safe, and environmentally friendly heating systems are critical to ensuring drug quality and production efficiency. The following sections will elaborate on the advantages of thermal oil boilers in the pharmaceutical industry.

4.1. High Efficiency

Thermal oil boilers exhibit extremely high thermal efficiency, making them perform exceptionally well in the pharmaceutical industry. Unlike traditional steam boilers, thermal oil boilers can achieve high-temperature heating at lower pressures, significantly reducing heat energy loss. Their efficiency advantage is evident in the complete combustion of fuel and the high effectiveness of heat transfer, resulting in significantly higher energy utilization rates. For example, thermal oil boilers can operate within an efficiency range of 85% to 90%, whereas traditional steam boilers typically operate at 70% to 80%. This efficiency difference translates into significant cost savings and increased production efficiency over long-term operations.

4.2. Precise Temperature Control

Thermal oil boilers can achieve precise temperature control, which is crucial for the pharmaceutical industry. Many reactions and processing steps in pharmaceutical production require very strict temperature control, as even slight temperature fluctuations can affect the quality and purity of the drugs. Thermal oil boilers, through advanced control systems, can maintain temperature control within a ±1°C range, ensuring the stability of process conditions. For example, in certain chemical reactions, precise temperature control can increase reaction conversion rates and reduce the formation of by-products, thereby improving the purity and yield of the drugs.

4.3. Safety

Thermal oil boilers have significant safety advantages, particularly suitable for the high safety requirements of the pharmaceutical industry. Their low-pressure operation characteristics reduce pressure-related safety hazards and lower the risk of boiler explosions. Additionally, thermal oil boilers are designed with fire and explosion prevention measures and equipped with various safety devices such as over-temperature protection, over-pressure protection, and dry-burning protection. These features ensure timely responses and prevent dangerous occurrences during operation. Compared to traditional high-pressure steam boilers, the safety features of thermal oil boilers make them widely adopted in pharmaceutical enterprises.

4.4. Environmental Friendliness

Thermal oil boilers also excel in environmental protection. Their high efficiency and low emissions make them ideal choices for environmentally friendly heating equipment. Thermal oil boilers have high combustion efficiency, reducing fuel consumption and thereby lowering emissions of carbon dioxide, nitrogen oxides, and other pollutants. Additionally, thermal oil systems can recover and reuse waste heat, further enhancing energy utilization and achieving energy-saving effects. For example, in pharmaceutical plant applications, thermal oil boilers can reuse waste heat generated during production, reducing energy waste and lowering the company's carbon footprint.

5. EPCB Case Study: Successful Application of Thermal Oil Boilers in a Pharmaceutical Plant

EPCB is a leading company specializing in the design, manufacturing, and sales of boilers, renowned in the market for its efficient, environmentally friendly, and safe boiler products. With over 70 years of industry experience and technological accumulation, EPCB is dedicated to providing comprehensive thermal energy solutions for its customers.

In the pharmaceutical industry, EPCB's thermal oil boilers are highly praised for their excellent product quality and technical support. These boilers, with their high efficiency, precise temperature control, safety, and environmental friendliness, perfectly meet the stringent requirements of the pharmaceutical industry, ensuring the continuity of production processes and the stability of drug quality. EPCB has numerous successful case studies in the pharmaceutical field, demonstrating its professional expertise and reliability in this industry.

5.1 Project Introduction

A pharmaceutical plant faced challenges requiring precise temperature control, high efficiency, and safety during production. Traditional steam boilers could not meet their strict temperature control requirements, had high energy consumption, and incurred high operational costs. Additionally, the client needed to meet stringent environmental regulations, reduce emissions, and achieve energy-saving goals.

5.2 Provided Solution

EPCB provided the pharmaceutical plant with an advanced thermal oil boiler solution. After detailed on-site inspection and needs analysis, EPCB designed and installed a highly efficient thermal oil boiler system. This system included a burner, thermal oil boiler body, circulation pump, expansion tank, temperature control system, and a series of safety devices, ensuring efficient and safe operation.

EPCB implemented several key improvements during the project, including optimizing burner design to improve combustion efficiency, enhancing boiler body structure to increase heat transfer efficiency, and installing advanced temperature control systems for precise temperature management. Comprehensive safety devices were also installed to ensure timely response and prevention of any dangerous situations during operation.

5.3 Results and Benefits

By applying EPCB's thermal oil boiler, the pharmaceutical plant significantly improved production efficiency. The efficient energy utilization and precise temperature control made the production process more stable and efficient. Compared to traditional steam boilers, the thermal oil boiler reduced fuel consumption, achieving significant energy savings and reducing operational costs.

Additionally, the multiple safety devices equipped in the EPCB boiler greatly enhanced the system's safety, reducing operational risks. Advanced desulfurization and dust removal devices effectively reduced harmful gas emissions, ensuring compliance with strict environmental standards and better adherence to relevant regulations and policies.

5.4 Customer Feedback and Opinions

The customer expressed high satisfaction with the thermal oil boiler system provided by EPCB. They particularly appreciated the system's high efficiency and safety, as well as EPCB's professional service and technical support during the project implementation. Customer feedback indicated that the application of the thermal oil boiler not only improved production efficiency and reduced energy consumption but also greatly enhanced the company's environmental performance and market competitiveness.

6. Maintenance and Servicing of Thermal Oil Boilers

Thermal oil boilers are highly efficient and stable heating equipment, widely used across various industries. To ensure their continuous, efficient, and safe operation, regular maintenance and servicing are essential. EPCB Boiler will now share some maintenance and servicing tips for thermal oil boilers, helping you extend equipment life, improve operational efficiency, and ensure production safety.

6.1 Daily Maintenance

Daily maintenance of thermal oil boilers involves a series of meticulous daily inspection tasks, including confirming that the burner ignites properly and burns stably, monitoring the thermal oil level to prevent adverse effects on the system, and continuously monitoring system pressure and temperature to ensure they remain within safe set ranges and quickly responding to any abnormalities. Additionally, checking the operational status of the electrical control system is crucial to ensure all sensors and controllers are functioning correctly.

It is especially critical to maintain the cleanliness of the boiler and its auxiliary equipment, as the accumulation of ash and oil can significantly reduce heat dissipation efficiency and combustion performance, increasing operational costs and the risk of equipment failure. Therefore, regular cleaning and maintenance operations to prevent the buildup of dust and oil are vital to ensuring the normal operation of all parts of the thermal oil boiler and the overall stability of the system.

6.2 Regular Inspection and Servicing

Regular inspection and servicing of thermal oil boilers are necessary to prevent equipment failure and ensure safe operation. Key steps include inspecting and replacing parts to ensure good condition of components, cleaning and clearing the interior of the boiler, coils, and pipelines to remove carbon deposits and impurities, and reassembling and thoroughly testing the system to ensure it returns to normal operation. During the inspection and servicing process, safety measures are equally crucial: wearing protective equipment to ensure personal safety, maintaining good ventilation in the work area to prevent fire risks, and using proper tools to avoid equipment damage and personal injury. Strict adherence to these steps and measures will effectively improve the efficiency and safety of the thermal oil boiler's inspection and servicing.

6.3 Troubleshooting Common Problems

Common issues encountered during the operation of thermal oil boilers include incomplete combustion (which may be caused by burner faults, poor fuel quality, or insufficient air supply, requiring inspection and cleaning of the burner, fuel replacement, and air supply adjustment), abnormal oil levels (possibly due to thermal oil leaks or refill system failures, necessitating inspection and repair of leaks and servicing of the refill system), pipeline leaks (often due to aging pipelines, loose joints, or seal failure, requiring replacement of aging pipelines, tightening of joints, and replacement of seals), and abnormal temperature and pressure (usually caused by faults in the temperature control system or sensor failures, requiring servicing of the temperature control system and replacement of faulty sensors).

In the event of an emergency, the following comprehensive emergency response plan should be implemented: immediately shut down the system to prevent further damage and danger, quickly isolate the danger area to prevent unnecessary personnel entry and ensure site safety, promptly report the fault details to relevant personnel, and record the cause, process, and result of the fault for future inspection and preventive work. Emergency repairs should be carried out as quickly as possible to restore the equipment to normal operation while ensuring personnel safety. This series of measures aims to respond quickly, effectively control, and minimize the impact of faults on production.

FAQ

What is the operating temperature range for thermal oil boilers?

The operating temperature range for thermal oil boilers generally falls between 200°C and 350°C. Different models and brands may have slightly different optimal operating temperatures, which should be confirmed according to the equipment's manual or by consulting the manufacturer. During operation, it is crucial to maintain the boiler temperature within the recommended range to ensure stability and efficiency in heat transfer.

What is the lifespan of a thermal oil boiler?

The typical lifespan of a thermal oil boiler is around 15 years. However, this lifespan can vary based on factors such as the specific condition of the equipment, the operating environment, and the quality of maintenance. To extend the lifespan of a thermal oil boiler, regular maintenance and inspections are recommended to ensure proper operation. Generally, replacing the equipment after 5-10 years is considered reasonable, but this should be based on the actual condition of the equipment.

How can the energy efficiency of a thermal oil boiler be improved?

Improving the energy efficiency of a thermal oil boiler can be achieved through the following methods:

· Install an Air Preheater: Utilize the waste heat from flue gases to preheat the air entering the boiler, thereby improving combustion efficiency.

· Use a Waste Heat Boiler for Heat Recovery: Recover heat from flue gases to heat water or generate steam, saving fuel.

· Optimize Combustion Parameters: Adjust combustion parameters based on fuel type and load variations to ensure stable and complete combustion.

· Enhance Insulation Measures: Reduce heat loss from the boiler and increase energy utilization efficiency.

· Regular Maintenance: Maintain the boiler in good working condition to reduce efficiency losses caused by equipment malfunctions.

What should be noted during the operation of a thermal oil boiler?

When operating a thermal oil boiler, the following safety considerations should be observed:

· Strictly Control Operating Temperature: Ensure the boiler operates within the specified temperature range to avoid issues like oil deterioration or aging.

· Regular Inspections and Maintenance: Perform regular inspections and maintenance to ensure safe operation.

· Prevent Leaks: Check the boiler and pipeline system for leaks, and address any leaks immediately.

· Ensure Proper Ventilation: Maintain good ventilation to prevent the accumulation of fuel and thermal oil vapors, which could lead to fire or poisoning incidents.

· Follow Operating Procedures: Operators should strictly adhere to operating procedures and safety regulations to ensure safe equipment operation.

What are the environmental performance characteristics of thermal oil boilers?

Thermal oil boilers excel in environmental performance. Compared to traditional steam boilers and other heating devices, thermal oil boilers do not produce wastewater or exhaust gases during the heating process, resulting in minimal environmental impact. Additionally, thermal oil boilers have high thermal efficiency, making full use of fuel energy and reducing energy consumption. They can also be adjusted and controlled based on different production process needs, offering strong adaptability.

Conclusion

The importance of thermal oil boilers in the pharmaceutical industry is undeniable. Their efficiency, precise temperature control, safety, and environmental friendliness make them ideal heating devices for pharmaceutical processes. With efficient heat transfer and stable operation, thermal oil boilers provide a solid foundation for the continuous advancement of the pharmaceutical industry.

EPCB boiler’s successful case studies with thermal oil boilers demonstrate significant advantages in improving production efficiency, energy savings, and safety. With its expertise and extensive experience in the pharmaceutical sector, EPCB boiler has provided customized solutions that have been highly praised by customers. Regular maintenance and servicing have ensured the long-term stable operation of the equipment, further solidifying its importance in the pharmaceutical industry.

In summary, the diverse advantages of thermal oil boilers in the pharmaceutical industry make them key equipment for enhancing production efficiency. We encourage pharmaceutical plant managers to consider the application of thermal oil boilers. By introducing this advanced equipment, not only can production processes be optimized, but higher economic and social benefits can also be achieved, laying a solid foundation for sustainable development. If you are interested in EPCB's thermal oil boilers, please feel free to contact EPCB Boiler.

Related Article:

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler