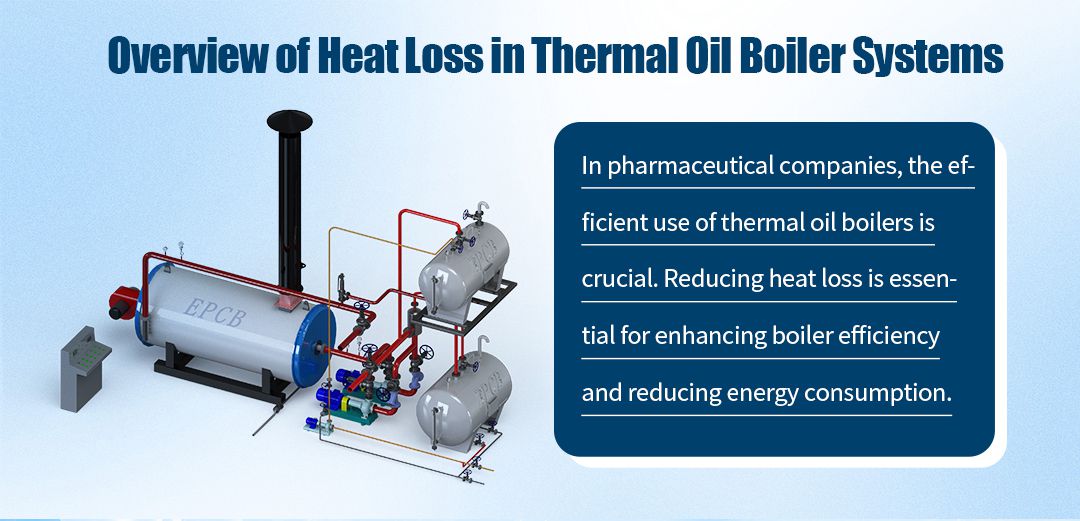

1. Overview of Heat Loss in Thermal Oil Boiler Systems

Heat loss in thermal oil boiler systems significantly impacts overall efficiency, making it a critical issue in the pharmaceutical industry. Thermal oil boilers are widely used in this industry due to their ability to provide precise and stable high-temperature heat, especially in key processes such as distillation, drying, and reactor heating. These processes require consistent temperatures to ensure product quality, and thermal oil, as a heat transfer medium, allows the boiler to operate at high temperatures under low pressure, ensuring safe and efficient production.

However, heat is often lost through radiation from the boiler surface, convection loss in the pipelines, and leakage from insulation layers. This results in the boiler consuming more fuel to maintain the required temperature, thereby increasing operating costs and reducing efficiency. To ensure the boiler operates efficiently and control costs, reducing heat loss is essential. By improving insulation, conducting regular maintenance, and adopting advanced control systems, pharmaceutical companies can effectively reduce heat loss, thereby improving boiler efficiency, saving energy, and reducing emissions. This not only aligns with the industry’s sustainability goals but also ensures temperature stability during the production process.

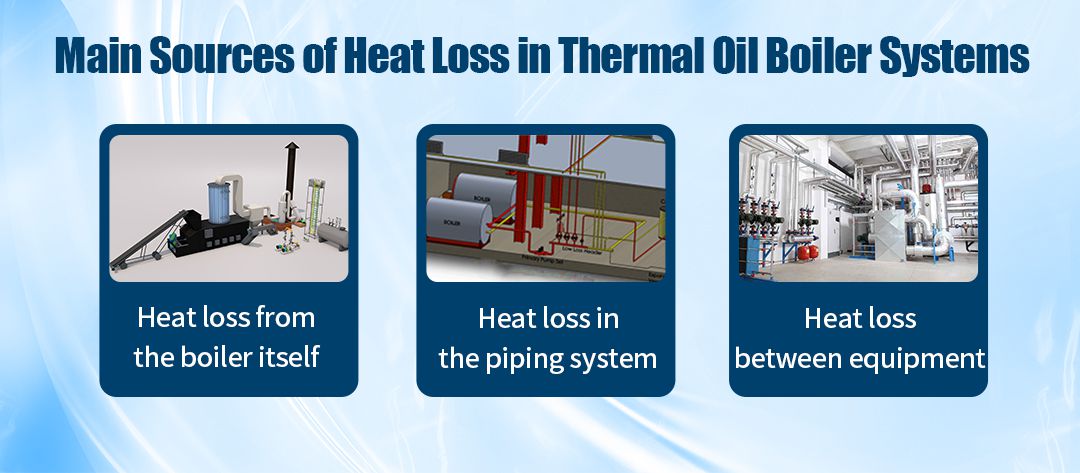

2. Main Sources of Heat Loss in Thermal Oil Boiler Systems

Maintaining efficient heat transfer is crucial for the operation of thermal oil boiler systems. Although these systems are designed to provide stable high-temperature heat, in practice, heat loss is a major issue affecting boiler efficiency and energy consumption. To fully understand how to optimize the thermal efficiency of the system, it is necessary to explore the main sources of heat loss in thermal oil boiler systems. This includes heat loss from the boiler body, heat loss in the piping system, and heat dissipation between equipment.

Heat Loss from the Boiler Body

Heat loss from the boiler body primarily manifests in heat dissipation from the boiler shell and flue. When the boiler shell and flue are not effectively insulated, significant amounts of heat are lost. Additionally, the aging and deterioration of insulation materials can increase heat dissipation, reducing the overall thermal efficiency of the boiler.

Heat Loss in the Piping System

During long-distance transmission, heat gradually dissipates in the piping system, especially when adequate insulation measures are not taken. This loss is particularly noticeable in the absence of proper thermal insulation. Furthermore, sealing issues at pipe joints can lead to heat leakage, increasing energy consumption and reducing system efficiency.

Heat Loss Between Equipment

Heat loss between equipment mainly includes heat dissipation from heat exchangers and heating equipment. During operation, heat exchangers may experience heat loss, affecting the overall efficiency of the system. Additionally, the heat dissipation from high-temperature equipment can further reduce the system’s thermal efficiency.

3. Effective Methods to Reduce Heat Loss

In the operation of thermal oil boiler systems, heat loss is a key factor affecting system efficiency and energy costs. The loss of heat not only reduces the overall performance of the boiler but also increases energy consumption and operating expenses. To optimize boiler system performance and achieve energy-saving goals, taking effective measures to reduce heat loss becomes crucial. Below, we explore some effective methods that can not only significantly improve the system's thermal efficiency but also help pharmaceutical companies lower energy costs and promote sustainable development.

· Upgrade Insulation Materials

Using efficient insulation materials is an important measure to reduce heat loss in boilers and pipelines. High-quality insulation materials can significantly decrease heat dissipation, thereby improving the overall thermal efficiency of the system. Additionally, regular inspection and replacement of aging insulation layers to ensure they maintain optimal thermal performance are critical.

· Improve Boiler Design

Optimizing the design of the boiler shell and flue can help reduce heat outflow. For example, enhancing the insulation layer of the boiler shell can effectively reduce heat dissipation. Moreover, adding extra insulation inside the boiler can further increase thermal efficiency and reduce unnecessary energy loss.

· Regular Maintenance and Inspection

Regular inspections and maintenance of all components in the boiler system are fundamental to ensuring efficient operation. Monitoring key indicators of heat loss and adjusting operations based on actual conditions can reduce heat loss and enhance the overall performance of the boiler.

· Install Heat Recovery Devices

Installing waste heat recovery devices can utilize the excess heat in other production processes, further improving energy efficiency. Using devices such as condensing economizers to recover and reuse waste heat not only reduces energy consumption but also enhances the system's economic efficiency.

· Optimize Pipeline Layout

Shortening the length of thermal oil pipelines can effectively reduce heat loss during transmission. Additionally, improving the sealing at pipeline connections to prevent heat leakage is an important measure for improving system thermal efficiency. Optimizing the pipeline layout ensures that heat is more effectively delivered to the target location, minimizing unnecessary energy loss.

Through decades of technological accumulation, EPCB Boiler has continuously improved and optimized solutions to meet customer needs, especially achieving remarkable success in reducing heat loss. Therefore, when providing comprehensive heat loss reduction solutions for customers, EPCB places particular emphasis on strengthening the application of insulation materials, optimizing boiler design, equipping efficient waste heat recovery devices, and improving pipeline layout. These refined technical supports have not only significantly reduced heat loss in boiler systems but have also effectively helped enterprises lower energy costs, improve production efficiency, and ultimately promote sustainable development.

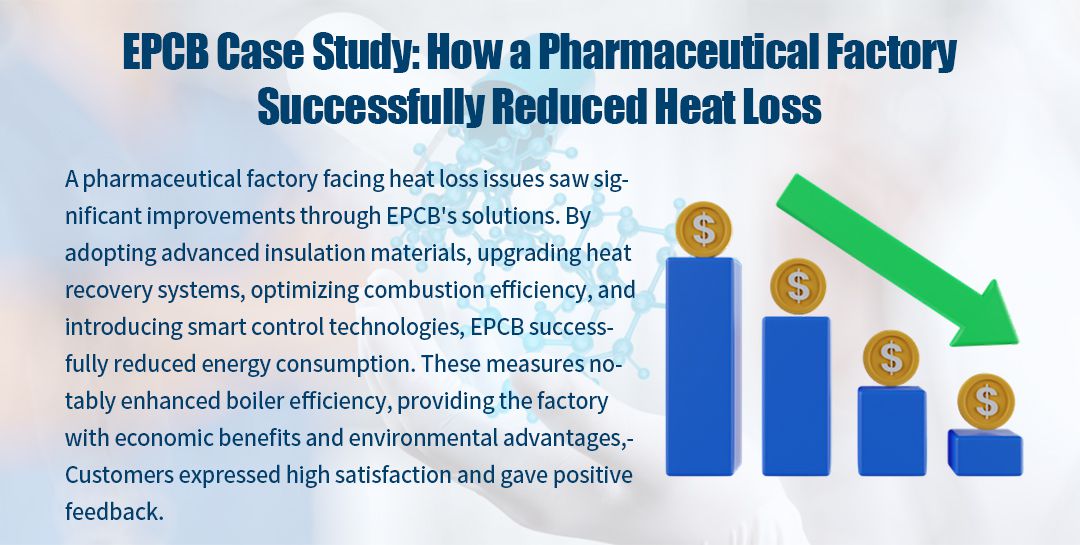

4. EPCB Case Study: How a Pharmaceutical Plant Successfully Reduced Heat Loss

As a leading boiler manufacturer in the industry, EPCB is committed to helping customers optimize energy use and reduce operating costs through advanced technology and innovative solutions. We focus on providing efficient and reliable boiler systems and have accumulated numerous successful cases in reducing heat loss.

Project Background

A pharmaceutical plant faced severe heat loss issues during its production process. The plant required stable high-temperature heat in key processes such as distillation, drying, and reactor heating, but the existing thermal oil boiler system experienced significant heat dissipation, leading to energy waste and low production efficiency. With increasingly stringent environmental regulations and rising energy costs, reducing heat loss became an urgent issue that needed to be addressed.

EPCB developed a comprehensive heat loss control solution tailored to the specific needs of the pharmaceutical plant. The following are the specific measures we implemented:

· Upgrade Insulation Materials

The existing insulation layer was inspected and maintained to ensure stable performance, and aging parts were replaced promptly. High-efficiency insulation materials were used to replace the aging insulation layer, reducing heat loss in the boiler and pipelines.

· Improve Boiler Design

The boiler shell and flue design were optimized to reduce heat outflow. Additional insulation layers were added inside the boiler to increase overall thermal efficiency.

· Regular Maintenance and Inspection

Regular inspections of all components in the boiler system were carried out, and timely repairs and maintenance were conducted to prevent heat loss. Key heat loss indicators were monitored, and operational strategies were adjusted based on data to ensure optimal system performance.

· Install Heat Recovery Devices

A waste heat recovery device was installed, allowing the excess heat to be used in other production processes, further improving energy efficiency. A condensing economizer was employed to recover and utilize waste heat, further enhancing the system’s economic efficiency and thermal energy utilization.

· Optimize Pipeline Layout

The length of the thermal oil pipelines was shortened to reduce heat loss during transmission. The sealing at pipeline connections was improved to prevent heat leakage.

Results and Benefits

Through the implementation of the above measures, the pharmaceutical plant significantly reduced heat loss, and overall energy efficiency improved by 20%. Production efficiency was greatly enhanced, and operating costs were significantly reduced. The customer expressed high satisfaction with EPCB’s solution, particularly appreciating our professional expertise and service. The plant’s production director commented, “EPCB not only provided us with an efficient solution but also ensured smooth system operation through professional service throughout. Their solution helped us achieve both energy savings and environmental protection.”

5. Advantages of Reducing Heat Loss

In the operation of thermal oil boiler systems, heat loss not only leads to energy waste but also significantly increases operating costs and the negative impact on the environment. However, by effectively reducing heat loss, companies can achieve significant improvements in various aspects. The following are the main advantages of reducing heat loss, which not only enhance the overall efficiency of the boiler but also help companies save costs, improve production stability, and achieve notable environmental benefits. We will now discuss these advantages in detail and their positive impact on business operations.

· Cost Savings

Reducing heat loss directly lowers fuel consumption, resulting in significant operating cost savings. By optimizing insulation, improving design, and increasing system efficiency, companies can effectively reduce energy waste and lower fuel expenses. This not only reduces daily operating costs but also brings notable economic benefits, allowing companies to maintain a cost advantage in a competitive market.

· Improved Boiler Efficiency

By reducing heat loss, the overall efficiency of the boiler is enhanced. Increased efficiency means the boiler can more effectively convert heat energy, thus improving the stability and reliability of pharmaceutical production processes. Stable heat supply ensures consistency in production processes, reduces production issues caused by temperature fluctuations, and further optimizes production workflows and product quality.

· Environmental Benefits

Reducing heat loss also brings significant environmental benefits. By lowering fuel consumption and reducing energy waste, emissions are also reduced, helping companies comply with strict environmental regulations. The positive impact of optimized systems on the environment not only enhances a company’s green image but also strengthens its sense of social responsibility, further boosting its public image and market reputation.

6. Considerations for Implementing Heat Loss Control

In modern industrial production, energy efficiency has become a crucial aspect of a company’s competitiveness. With rising energy costs and increasingly stringent environmental requirements, reducing heat loss has become a key measure to optimize production processes and lower operating costs. However, to achieve this goal, companies must comprehensively consider several factors when implementing heat loss control measures. The following will discuss the considerations for implementing heat loss control from the perspectives of project planning, technical support, and safety management.

Project Planning In the project planning stage, it is essential to thoroughly evaluate the existing system’s heat loss situation. This includes identifying potential heat loss points in the system using methods such as thermal imaging and thermodynamic calculations. Based on the evaluation results, a detailed implementation plan and budget should be developed to ensure that the required resources and timelines meet project needs. It is also crucial to prioritize control measures to maximize heat loss reduction and improve system efficiency within the available budget.

Technical Support Technical support is key to the successful implementation of a heat loss control project. Companies should seek professional technical assistance, especially when dealing with the installation and optimization of complex heat exchangers or insulation materials. Professional technical personnel can provide valuable advice and guidance. Additionally, to ensure the smooth operation of the new system, operators must receive adequate training to familiarize them with the new system’s operational and maintenance requirements. This not only helps reduce the risk of operational errors but also improves the system’s overall efficiency.

Safety Management Safety management is critical throughout the implementation process. Adhering to relevant safety regulations and standards is essential to prevent accidents during installation, commissioning, and operation. Appropriate safety measures, such as protective devices and emergency plans, should be implemented on the construction site to handle unexpected situations. Furthermore, after the system is put into use, regular inspections and adjustments should be carried out to ensure continuous efficient operation and timely elimination of potential safety hazards. Preventive maintenance not only extends the equipment’s service life but also prevents accidents.

FAQ

What is the payback period for heat loss control investment?

The payback period typically depends on the scale of the project and the control measures adopted. Generally, the payback period for a heat loss control project ranges from 1 to 3 years. With precise heat loss assessment and reasonable budget planning, companies can achieve energy savings and cost recovery more quickly.

Will heat loss control affect production?

Heat loss control measures can be implemented in phases or during non-production periods to minimize disruption to production. Additionally, companies can choose heat loss control methods that do not affect key production equipment, ensuring continuous operation of the production line.

Are special equipment or tools needed to reduce heat loss?

Reducing heat loss usually requires the use of advanced insulation materials, heat recovery devices, or thermal imaging equipment. These devices and technologies can effectively reduce system heat loss and improve overall energy efficiency.

What are the long-term benefits of reducing heat loss?

In the long run, reducing heat loss not only significantly lowers energy costs but also reduces greenhouse gas emissions, improving a company’s environmental image. Continuous improvements in energy efficiency also lead to more stable production and higher profit margins.

How to choose a suitable technology partner for the company’s needs?

When choosing a technology partner, it is advisable to assess their professional experience, technical capabilities, and industry reputation. Ensure that the partner can provide comprehensive solutions and customize heat loss control plans according to the company’s needs.

Conclusion

Reducing heat loss is crucial for the pharmaceutical industry, as it directly affects the efficiency of boiler systems and relates to cost control and environmental responsibility. By implementing effective heat loss control measures, pharmaceutical plants can significantly improve energy efficiency, reduce production costs, and minimize environmental burdens, which is particularly important in light of increasingly stringent environmental regulations.

Looking ahead, with the continuous advancement of technology, more efficient insulation materials, intelligent heat monitoring systems, and advanced heat recovery devices will be widely used in the pharmaceutical industry. These technologies will help companies further reduce energy waste, improve production efficiency, and provide strong support for the industry's sustainable development.

We encourage pharmaceutical plants to actively evaluate and optimize their existing systems, and with professional technical support, implement advanced heat loss control measures. This will not only help companies enhance their market competitiveness but also make a greater contribution to energy conservation and emissions reduction, promoting the industry’s transition toward a greener, more intelligent future.If you have any questions about the use of the boiler, welcome to EPCB Boiler, and we will serve you wholeheartedly.

Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Thermal Oil Boiler

Thermal Oil Boiler Hot Water Boiler

Hot Water Boiler Steam Boiler

Steam Boiler Hot Water Boiler

Hot Water Boiler